GoSmarter AI Blog

5 Best Practices for Managing Manufacturing Documentation

Standardise, digitise and automate manufacturing records to improve traceability, version control and audit readiness.

Read More: 5 Best Practices for Managing Manufacturing Documentation

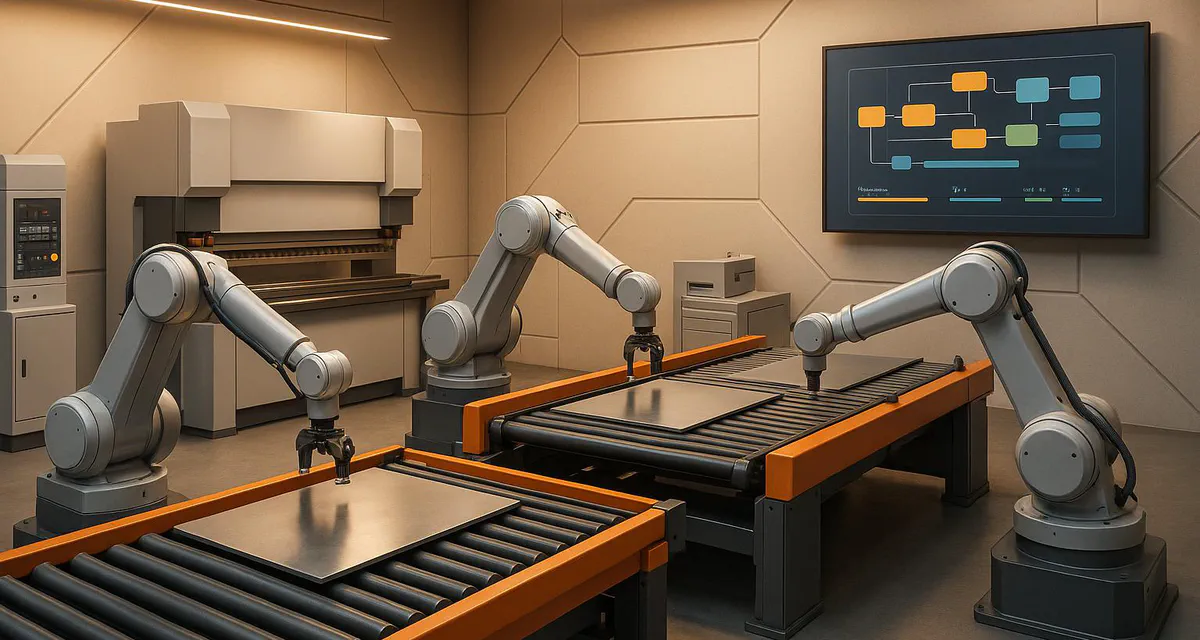

The Complete Guide to Streamlining Metal Fabrication Operations

How UK metal fabricators can reduce waste, cut lead times and boost output using workflow mapping, KPIs, AI scheduling and automation.

Read More: The Complete Guide to Streamlining Metal Fabrication Operations

Mill Test Certificate Management: Common Questions Answered

Clear answers on Mill Test Certificates: what MTCs contain, EN 10204 types, verification, common issues and AI automation with digital audit trails.

Read More: Mill Test Certificate Management: Common Questions Answered

7 Ways to Reduce Paperwork in Metal Manufacturing

Seven digital strategies—AI docs, MES, cloud inventory, ERP and e-signatures—to cut paperwork, speed production and improve compliance.

Read More: 7 Ways to Reduce Paperwork in Metal Manufacturing

How to Automate Mill Certificate Management in 5 Steps

Reduce errors and speed compliance by automating mill certificate handling: assess processes, choose technology, integrate, validate, and train teams.

Read More: How to Automate Mill Certificate Management in 5 Steps

Compliance Management Checklist for Metals Manufacturers

Comprehensive checklist for metals manufacturers covering UK REACH, import/export rules, ISO standards, supplier qualification, traceability, emissions and digital tools.

Read More: Compliance Management Checklist for Metals Manufacturers

Wales Tech Week 2025: Connecting, Showcasing, and Inspiring Welsh Innovation

Wales Tech Week 2025 brought together leading figures from the Welsh tech ecosystem to connect, share insights, and celebrate innovation. Highlights included discussions on digitalisation in manufacturing, honest conversations about the role of failure in entrepreneurship, and a strong focus on collaboration and funding for the sector. Nightingale HQ was recognised with the Best Greentech Award for its work in sustainable manufacturing, reflecting the event’s emphasis on impactful technology and the growing global reputation of Welsh tech.

Read More: Wales Tech Week 2025: Connecting, Showcasing, and Inspiring Welsh Innovation

Nightingale HQ team attend UK Metals Expo

Nightingale HQ team attend UK Metals Expo on 10 and 11 September at the NEC, Birmingham.

Read More: Nightingale HQ team attend UK Metals Expo

CBAM Explained: The Financial Case for Cutting Scrap

The steel industry faces increasing pressure to decarbonise, with the EU’s Carbon Border Adjustment Mechanism (CBAM) set to become a decisive factor by 2026. Scrap is no longer just a production inefficiency it directly increases reported emissions and carbon costs. For Finance and Sustainability Managers, reducing scrap is now central to meeting carbon targets and protecting margins.

Read More: CBAM Explained: The Financial Case for Cutting Scrap

Smart Cuts, Less Scrap: A 1D Cutting Stock Problem

In rebar manufacturing, scrap directly impacts profitability and sustainability, making efficient production essential. Mathematical optimisation, particularly the 1D Cutting Stock Problem, helps minimise waste by determining the most efficient way to cut raw steel bars into required lengths while reducing leftover material.

Read More: Smart Cuts, Less Scrap: A 1D Cutting Stock Problem