Material Yield Planner to Maximize Efficiency

- Steph Locke

- Blog , Free tools

- February 9, 2026

Table of Contents

Optimise Your Production with a Material Yield Planner

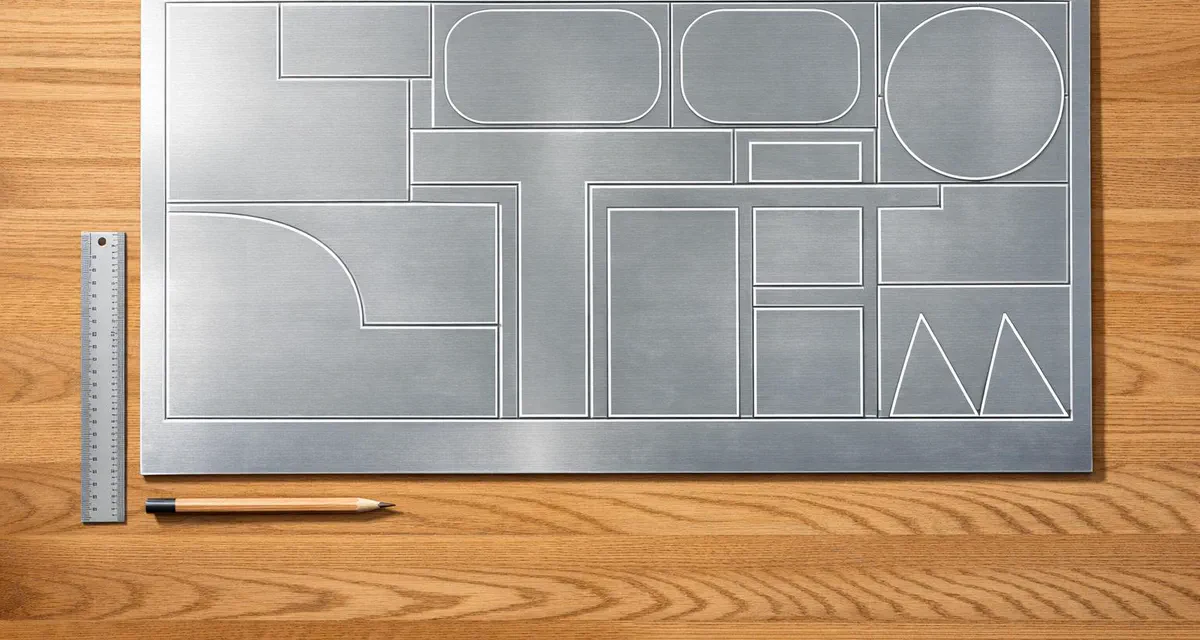

In the world of manufacturing and fabrication, efficiency is everything. Wasting raw materials isn’t just a hit to your budget; it’s a missed opportunity to streamline operations. That’s where a tool like the Material Yield Planner comes in, helping you calculate exactly how many parts you can extract from a given sheet or slab while minimising scrap. Whether you’re cutting metal, wood, or textiles, precision in planning can transform your workflow.

Why Material Efficiency Matters

Every inch of unused material adds up over time, especially in high-volume production. By using a calculator designed for yield optimisation, you ensure that each piece of stock is used to its fullest potential. This not only cuts costs but also supports sustainable practices by reducing waste. Imagine knowing before you even start cutting how to arrange parts for maximum output—pair that with accounting for kerf loss, and you’ve got a recipe for smarter fabrication.

A Tool for Every Workshop

From small-scale crafters to industrial manufacturers, planning material usage is a universal need. A reliable yield calculator takes the guesswork out of the equation, letting you focus on creating rather than calculating. Try it out and see the difference in your next project!

2D Exploration

This is our first foray into the 2D problem. In our core application GoSmarter.ai we have a much more in-depth production planner for 1D challenges. You can take your stock and orders needing fulfillment to produce a detailed cutting plan and stock pick-list as a first draft.

FAQs

How does the Material Yield Planner account for cutting loss?

When you input a kerf or cutting loss value, the tool factors in the extra space taken up by each cut. Think of it as the width of your saw blade or laser path. It adjusts the layout to ensure you’re not overestimating how many parts can fit, giving you a realistic yield number you can trust for planning.

Can I use this tool for materials other than sheets?

Absolutely, though it’s designed with flat materials like metal sheets, wood panels, or fabric in mind. If you’re working with linear materials or 3D blocks, the logic might not fully apply. Stick to 2D layouts for best results, and make sure your dimensions are consistent in units—metres, inches, whatever you prefer!

Why are the part counts rounded down?

We round down to whole numbers because you can’t use a fraction of a part in real production. It’s all about practicality—giving you a number you can actually work with on the shop floor. The leftover material calculation helps you see what’s still usable for smaller projects or future cuts.