Manual vs Digital Inventory Tracking: Which Saves More Time?

- Steph Locke

- Blog

- December 9, 2025

Table of Contents

Digital inventory tracking saves more time than manual methods by automating processes, reducing errors, and providing real-time updates. Here’s why:

- Manual tracking involves physical counts, paper records, or spreadsheets, which are slow, error-prone, and labour-intensive.

- Digital systems use automation (e.g., barcodes, RFID tags) to log stock instantly, cutting down on repetitive tasks and delays.

- Digital tools improve accuracy, eliminate data entry mistakes, and simplify locating or updating records.

- Real-time visibility ensures better stock control, faster decision-making, and less time spent resolving discrepancies.

Quick Overview:

- Manual methods: Time-consuming, prone to errors, and hard to scale.

- Digital systems: Faster, more accurate, and better suited for growing businesses.

Switching to digital tracking may require upfront investment and training, but the long-term time savings and efficiency gains make it worthwhile for most operations.

How Manual Inventory Tracking Works

Manual inventory tracking relies on physical counts and updating records using either paper or digital spreadsheets [2].

Warehouse staff are tasked with conducting these physical counts, which are then used to manually update inventory records [1][5]. These counts might occur on a regular schedule, such as during end-of-year stocktakes, or whenever management decides they are necessary.

Ayushi Saxena, IT Support Manager at StockTake Online, explains:

Manual stocktaking means counting and recording inventory by hand using pen and paper or spreadsheets [1].

Paper records and spreadsheets remain widely used in manufacturing. Employees often log stock levels, sales, and purchases in physical notebooks [4]. While spreadsheets can help organise large amounts of data, they still require manual input, which increases the likelihood of errors [3].

Some manufacturers use a continuous manual inventory system, updating records in real time as items are received or dispatched. Others rely on periodic physical counts to assess stock levels [5]. Both methods demand dedicated staff to track purchases, sales, and other stock movements [2].

For example, when raw materials arrive, someone must record their arrival. As materials are used in production, records are updated again. Similarly, when finished goods leave the warehouse, the change is noted. While this approach is familiar and straightforward, it introduces inefficiencies that can disrupt operations.

Problems with Manual Tracking

Although simple, manual inventory systems come with several challenges that impact efficiency and costs.

Human error is one of the biggest issues. Every manual entry or count creates opportunities for mistakes - whether it’s a misread number or a typo - that can lead to compounding inaccuracies over time [3].

Time-consuming processes are another drawback. Physical stock counts pull staff away from their primary responsibilities, and the need to locate, count, and record each item individually makes the process inherently slow.

Record loss and security risks are also common. Paper records are easily misplaced or damaged, while both paper and spreadsheets are vulnerable to unauthorised access [1][4].

Limited real-time visibility is perhaps the most significant operational hurdle. Manual systems only provide snapshots of inventory at the time of the count, leaving businesses in the dark about current stock levels between updates. This lack of up-to-date information makes it harder to analyse trends or accurately forecast needs [3].

As Logos Logistics Distribution points out:

Manual tracking methods - such as spreadsheets, physical logs, or even verbal reporting - were once the norm for managing inventory. However, these outdated systems have become significant roadblocks for modern businesses [6].

Scalability challenges also arise as businesses grow. Adding more products, locations, or transactions often means hiring additional staff to handle the increased workload, making manual systems impractical for larger operations.

These issues lead to wasted time, higher costs, and missed opportunities. Every moment spent on manual counting or fixing errors is time that could be better spent on more productive tasks.

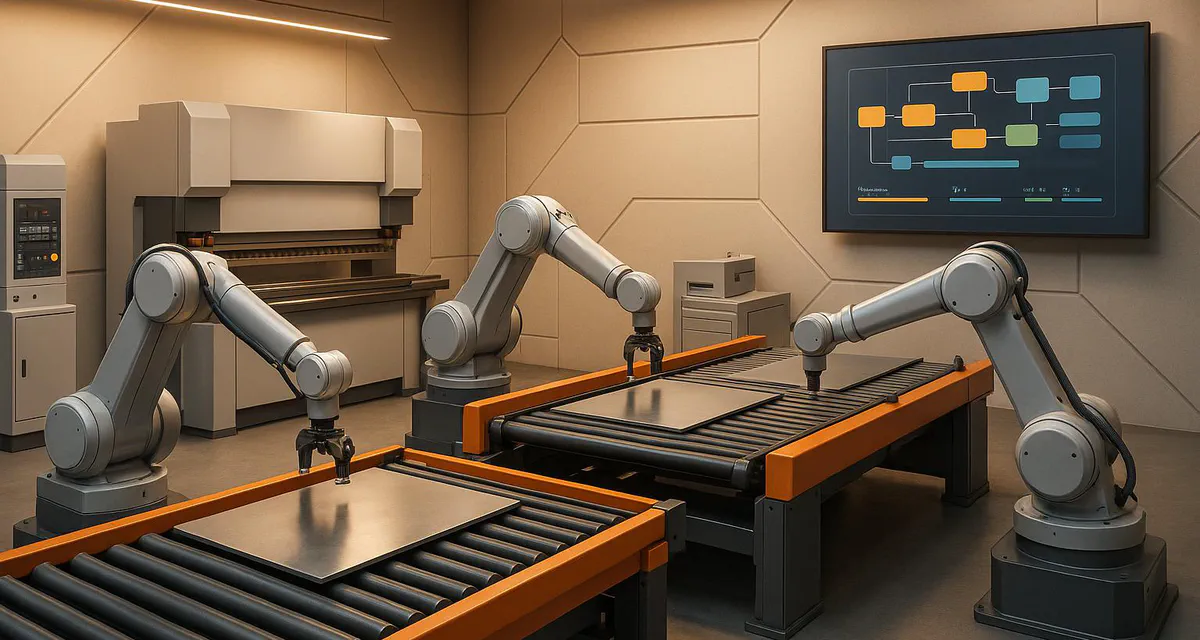

How Digital Inventory Tracking Works

Digital inventory tracking uses software and connected devices to automatically log stock data, replacing manual counts and paper records with a more efficient system.

The key difference is automation. Manual systems rely on someone physically recording each transaction, but digital systems capture this data automatically as it happens. For example, when raw materials arrive, sensors or scanners log them immediately. Similarly, when products are shipped out, the system updates in real time. This eliminates the errors and delays often associated with manual entry, making the entire process faster and more reliable.

Another advantage is centralised data. Digital systems store all inventory information in one shared platform, accessible to authorised staff from anywhere. A production manager can check stock levels from their office while someone on the warehouse floor views the same data simultaneously.

But these systems do more than just record numbers. They can identify trends, alert you when stock is running low, and even estimate future needs based on past activity. This shifts inventory management from a reactive process - only acting when stock runs out - to a proactive one that anticipates problems before they occur. These capabilities are powered by a combination of advanced technologies, which we’ll explore below.

Technologies Used in Digital Systems

Several technologies work together to make digital inventory tracking both efficient and reliable, each playing a unique role in capturing and managing data.

- Barcodes: Still widely used, barcodes assign a unique identifier to each item or batch. Staff scan these using handheld or fixed scanners, instantly updating the system without needing manual input. Barcodes remain a cost-effective and dependable option.

- RFID (Radio Frequency Identification) tags: These take automation a step further. Unlike barcodes, RFID tags transmit data wirelessly and don’t require line-of-sight scanning. This allows readers to detect multiple tags at once, even if they’re inside boxes or on pallets. For instance, an entire pallet can be logged in seconds, significantly speeding up operations.

- Cloud-based software: The backbone of modern systems, cloud platforms store data centrally and update it in real time. This eliminates the need for local installations and ensures that updates are reflected instantly across all devices, whether it’s a desktop in the office or a tablet in the warehouse. Automatic backups also protect data from loss.

- Mobile devices and tablets: These have become indispensable for warehouse staff. Equipped with scanning features and connected to the inventory system, they allow workers to update records on the spot, check stock levels, and process orders seamlessly.

- Integration capabilities: Digital systems can connect with other business tools, such as accounting software, production planning systems, and customer relationship management (CRM) platforms. This ensures that when inventory changes, the information is automatically shared across departments. For example, sales teams can confirm product availability, finance sees updated stock values, and production knows what materials are on hand.

- Automated alerts and notifications: These systems notify staff when stock levels fall below set thresholds, orders are ready, or discrepancies are detected. This keeps everyone informed without the need for constant monitoring, ensuring issues are addressed promptly.

Together, these technologies not only automate data tracking but also enhance overall efficiency and accuracy.

Benefits of Digital Tracking

Switching from manual to digital tracking offers clear, practical benefits that can transform day-to-day operations.

- Real-time stock visibility: With digital tracking, anyone with access can see up-to-date inventory levels at any time. This eliminates the need to wait for physical counts or second-guess whether spreadsheets are accurate. Production teams can confirm material availability instantly, and purchasing staff know exactly what needs reordering.

- Automated data logging: Every scan and movement is recorded automatically, saving time and reducing the risk of human error. Tasks that once took hours can now be completed in seconds, freeing up staff for more productive work.

- Fewer errors: Automation removes the risk of typos or misread numbers. Accurate data means less time spent fixing mistakes, investigating discrepancies, or dealing with stock shortages.

- Improved stock control: Digital systems provide insights into inventory trends, such as slow-moving items or fast sellers. This helps businesses maintain optimal stock levels - enough to meet demand without overstocking.

- Detailed audit trails: These systems log every change, including who made it, when, and why. This level of detail is invaluable during audits, quality checks, or when tracing products through the supply chain.

- Scalability: Digital systems grow with your business. Whether you’re adding new products, opening more warehouses, or handling higher transaction volumes, the system adapts without requiring additional staff for manual tracking.

- Seamless integration with business processes: When inventory data automatically flows into accounting, production, and sales systems, operations become more efficient. For example, low stock levels can trigger purchase orders, and production schedules can align with material availability. This eliminates the manual coordination that traditional systems often require.

Time Efficiency: Manual vs Digital

For manufacturers aiming to boost productivity, evaluating how time is spent on inventory management is essential. With manual tracking, every transaction - whether recorded in ledgers, spreadsheets, or on paper - demands direct human input. As transaction volumes grow, the time required for each entry increases significantly, making the process labour-intensive and prone to delays.

On the other hand, digital inventory systems take much of this burden off human hands. Tasks such as barcode scanning or RFID reading can log transactions in seconds, updating records in real time. This automation not only accelerates data entry but also reduces the time spent correcting errors or reconciling mismatched data. Additionally, digital systems allow for instant searches, cutting out the need to manually sort through stacks of records. The result? A clear edge in time efficiency that highlights the benefits of adopting digital methods.

Time Metrics Comparison

While the exact time saved depends on the specific operation, many manufacturers report significant reductions in time spent on crucial activities. These include recording stock movements, performing stock audits, locating item details, reconciling discrepancies, and generating reports. With these efficiencies, employees can redirect their energy towards more impactful tasks, such as improving quality control or refining processes.

It’s worth noting that setting up a digital system involves an upfront investment in installation, training, and migrating data. However, the time saved in daily operations often leads to a quick return on this investment. Over the long term, these cumulative time savings can help cut labour demands and reduce operating costs, laying the groundwork for broader improvements covered in later sections.

How Accuracy Affects Time Efficiency

Improved accuracy doesn’t just ensure better outcomes - it also saves time in ways that ripple across operations.

Every inventory error demands time-consuming corrections, whether it’s rechecking stock, investigating discrepancies, or updating records. These tasks eat into productivity and create unnecessary delays. Manual systems, prone to human error, often let mistakes slip through unnoticed until they cause bigger problems. For example, running out of essential stock or uncovering phantom inventory during an audit can bring operations to a standstill.

Digital systems, on the other hand, minimise these risks by automating processes and reducing the chance of errors at the data entry stage. With fewer mistakes to fix, the time spent on corrections drops significantly, creating a noticeable boost in overall efficiency. This connection between accuracy and time becomes even clearer when you look at specific types of errors and how long they take to resolve.

Fewer Errors with Digital Systems

Digital tracking systems excel at reducing errors by automating data entry. This is a game-changer because manual transcription errors - like miskeying a product code - are a major source of inventory inaccuracies. A single typo can lead to misplaced items or phantom stock entries, which can take hours to trace and fix.

But it’s not just about avoiding typos. Digital systems enforce real-time recording: if an item isn’t scanned, it doesn’t officially move. This creates a natural checkpoint, preventing unrecorded transactions and ensuring that every movement is logged accurately.

Stock discrepancies are another headache that digital systems help to avoid. When physical inventory doesn’t match the records, staff often have to stop everything to recount stock and investigate the mismatch. In large facilities with thousands of SKUs, this process can take an entire day. By maintaining more accurate records, digital systems help align physical counts with system data, reducing the need for these time-consuming checks.

Digital tracking also saves time by addressing inventory loss. Manual systems may show stock that doesn’t actually exist, leading teams to waste time searching for materials that aren’t there, delaying production schedules, and rushing replacement orders. Automated alerts in digital systems can flag unusual patterns - like sudden drops in inventory - that might indicate errors or even theft, allowing teams to act quickly before the issue escalates.

In addition to reducing errors, digital systems play a critical role in safeguarding the integrity of data.

Data Reliability and Protection

Paper records are notoriously fragile. Spills, misfiling, or physical damage can lead to lost or corrupted data, requiring hours - or even days - of recovery efforts. Digital systems eliminate this risk with automatic backups and cloud storage, ensuring records remain secure and accessible even during hardware failures or unexpected disruptions.

Standardisation is another major advantage. Manual systems rely on individuals following procedures perfectly, but inconsistencies inevitably creep in. One person might abbreviate a product name differently; another might record measurements in an unusual format. These variations force others to spend time clarifying entries or reformatting data for analysis. Digital systems enforce uniform data entry, ensuring every record follows the same structure and includes all necessary details.

Accessing records is also far quicker with digital systems. Instead of flipping through paper ledgers or hunting down a misplaced file, team members can pull up the information they need in seconds. Multiple people can view the same data simultaneously, eliminating delays caused by waiting for someone else to finish with a document. What might take 20 minutes with paper records - searching through pages or asking colleagues for help - can be done in moments digitally. Over time, these small efficiencies add up to hours of recovered productivity that can be directed towards more valuable tasks.

Other Benefits of Digital Tracking

When discussing digital inventory systems, the focus often lands on time savings. But the benefits go much deeper, touching every aspect of inventory management. From cutting down on excess stock to enabling better strategic decisions, these systems bring a range of advantages that are hard to overlook.

Manual tracking comes with hidden costs - correcting errors, dealing with excess inventory, and managing compliance issues all eat into resources. Digital systems eliminate these inefficiencies, delivering cost savings while improving overall control.

Lower Inventory Costs

Excess stock is a drain on resources. Every extra unit ties up cash, racks up storage fees, and risks becoming obsolete. Digital inventory systems solve this by offering precise, real-time visibility into stock levels. When purchasing decisions are based on accurate data rather than guesswork, businesses can order exactly what they need. This not only frees up capital but also reduces the strain on warehouse space.

These systems also ensure better inventory rotation, so older stock gets used first, minimising waste and write-offs. And let’s not forget the importance of avoiding stockouts. With continuous monitoring and timely reorder alerts, digital tracking helps prevent costly production delays and the expense of last-minute replacements.

Labour costs take a hit too - in a good way. By automating routine tasks like stock counting and data entry, digital systems allow employees to focus on more strategic activities that drive growth, rather than spending hours on manual inventory management.

The financial perks extend to supplier relationships as well. With accurate consumption data, businesses can negotiate better terms, explore bulk purchasing opportunities, and strengthen supplier partnerships. Transparency in data makes these negotiations more effective, ultimately lowering overall costs.

Better Decision Making with Real-Time Data

Cost control is just the beginning. Digital tracking systems also empower managers to make smarter decisions by providing real-time insights. Relying on end-of-month reports can leave businesses reacting to problems too late. Real-time data flips this script, enabling proactive planning and early interventions.

With instant visibility into stock levels, managers can spot trends before they escalate into issues. For example, instead of discovering a shortage when production grinds to a halt, they can detect patterns days in advance and act accordingly - whether that means adjusting orders, tweaking production schedules, or notifying customers about potential delays.

Another major advantage is the ability to identify emerging trends quickly. Digital systems can highlight unusual consumption rates or seasonal shifts that might take weeks to spot manually. If a material is being used faster than expected, managers can investigate immediately, addressing potential quality issues or changing demand before they disrupt operations.

Budgeting also becomes more precise with continuous financial insights. Instead of waiting for month-end reports to realise spending has gone off track, finance teams can monitor expenses in real time and make adjustments as needed. Shared access to accurate, up-to-date data enhances collaboration across departments. When production, purchasing, and finance teams are aligned, decisions are faster, more coordinated, and less prone to errors caused by inconsistent information.

With this level of precision and insight, managers can confidently align budgets, production plans, and purchasing strategies. Whether it’s expanding product lines, entering new markets, or scaling operations, detailed historical data combined with real-time updates allows for better scenario planning and reduces the risks tied to major business decisions.

Switching to Digital Inventory Tracking

Transitioning from manual to digital inventory tracking isn’t just about adopting new technology - it’s a complete shift in how your business handles and processes inventory data. While manufacturers may worry about disruptions or increased costs, with careful planning and a structured approach, the process can be seamless and lead to significant long-term benefits.

When done right, this change streamlines workflows, removes bottlenecks, and creates a foundation for sustainable efficiency. The key lies in setting clear goals and selecting a system that not only meets your current operational needs but also supports future growth.

Selecting a Digital System

Choosing the right digital inventory system is critical to making the most of this transition. The system you select should align with your company’s scale and specific challenges. For instance, a small manufacturer managing 50 SKUs will have vastly different needs compared to a mid-sized operation juggling thousands of components across multiple locations. What works for one may be overwhelming - or inadequate - for another.

Start by identifying your biggest pain points. Are stockouts a recurring issue? Is too much time spent on manual inventory counts? Are compliance requirements, like managing material certificates, causing headaches? Different systems excel in different areas, so understanding your priorities will help narrow the options.

While budget considerations are valid, they shouldn’t be the sole deciding factor. A low-cost system that doesn’t integrate with your existing ERP or production software could end up costing more in inefficiencies and workarounds. Look at the total cost of ownership, which includes implementation, training, ongoing support, and any necessary hardware like barcode scanners or mobile devices.

Scalability is another crucial factor. Your business is likely to grow, and switching systems down the line can be costly and disruptive. Look for a platform that can grow with you - whether that means handling more SKUs, adding users, or expanding to new locations. Be mindful of pricing models, as some systems charge per user or transaction, which could become expensive as your operations expand. Others offer more flexible pricing options that accommodate growth without adding unnecessary costs.

Integration capabilities are essential. If your new system can’t communicate with your accounting software, production planning tools, or supplier portals, you’ll end up with isolated data silos, defeating the purpose of going digital. Ask vendors about their API capabilities, pre-built integrations, and experience working with businesses similar to yours.

For metals manufacturers, industry-specific features are a must. Can the system handle mill certificates digitally? Does it track material grades, heat numbers, and compliance documentation? Can it effectively manage remnants and offcuts? Generic inventory software often falls short in these areas, adding to your workload instead of reducing it.

Finally, consider user experience, support, and training. A system that’s difficult to use will face resistance from your team, leading to poor adoption and continued reliance on manual methods. Request demos, involve the people who’ll use the system daily, and evaluate how intuitive the interface is. Comprehensive vendor support - such as onboarding assistance, dedicated account managers, and responsive technical help - can make all the difference between a smooth transition and a frustrating experience.

Managing the Transition

Once you’ve selected the right system, the focus shifts to implementing it with minimal disruption. A phased approach can help you manage the transition effectively while maintaining operational momentum.

Data migration is one of the most challenging steps. Whether your current inventory records are in spreadsheets, notebooks, or an outdated system, they need to be transferred accurately into the new platform. This is a great opportunity to clean up your data - remove obsolete SKUs, correct errors, standardise naming conventions, and verify quantities through physical counts. Starting with clean data ensures a smoother rollout and prevents long-term issues.

Consider running a pilot programme before a full-scale implementation. Test the new system with a specific product line, warehouse section, or team to identify potential issues and refine processes. This trial run also helps your staff gain familiarity with the system, making the broader rollout less daunting.

Staff training is critical. Your team needs to understand not just how to use the system, but also why it matters and how it will make their jobs easier. Address concerns openly and highlight how automation will free them from tedious tasks, allowing them to focus on work that requires human judgement. Provide role-specific training with hands-on sessions, and appoint internal champions to support their colleagues during the transition. While written documentation is helpful, hands-on practice is often the best way to learn.

Before going live, conduct thorough testing. Run parallel operations where possible, maintaining your old system while testing the new one. Compare outputs, ensure integrations work seamlessly, and verify that reports generate accurate data. This safety net helps catch and resolve any issues before they impact daily operations.

A successful transition not only preserves the efficiency gains of digital tracking but also improves workflows across your organisation. Keep communication open throughout the process. Regular updates on progress, timelines, and expectations help prevent misunderstandings and reduce anxiety. Celebrate small victories - like faster processes or errors caught early - to build confidence in the new system.

Treat implementation as an ongoing process rather than a one-time event. Schedule reviews at 30, 60, and 90 days to evaluate what’s working and address any challenges. This iterative approach ensures continuous improvement and long-term success.

GoSmarter’s platform offers solutions tailored to metals manufacturing, combining scalability, industry-specific features, and easy integration with minimal training requirements.

Conclusion

Switching to digital inventory tracking can significantly cut down on repetitive data entry and simplify essential documentation processes. For metals manufacturers, this means more time to focus on critical tasks that keep production running smoothly. The time savings shown in the metrics comparison highlight just how much more efficient digital systems are compared to manual methods.

If your current process still depends on manual data entry, it might be time to explore a digital solution. With thoughtful planning and a step-by-step approach, transitioning to a digital system can be seamless and highly rewarding.

FAQs

What are the key steps to move from manual to digital inventory tracking, and how can businesses implement it effectively?

To move from a manual to a digital inventory tracking system, start by taking a close look at how your current process works. Pinpoint where it falls short and where you can make improvements. This step lays the groundwork for choosing the right digital tools, such as inventory management software or barcode scanners, that fit your specific business needs.

For a smooth transition, make team training a priority. Ensure everyone understands how to use the new tools effectively, and consider rolling out the changes step by step to avoid unnecessary disruptions. Keep an eye on how things are progressing and gather feedback from your team to make adjustments and improve the system as needed.

How do digital inventory tracking systems work with current business processes, and what challenges might arise during implementation?

Digital inventory tracking systems are designed to fit smoothly into existing business operations. By automating tasks, they reduce manual labour, enhance accuracy, and deliver real-time updates. This not only streamlines workflows but also enables quicker, more informed decision-making.

That said, implementing these systems can come with hurdles. Initial costs, the time needed to train staff, and ensuring the new system works well with current software are common challenges. With thoughtful planning and a gradual roll-out, businesses can tackle these issues effectively, paving the way for a smoother transition and lasting advantages.

What are the most effective digital tools for inventory tracking, and how do they improve efficiency and accuracy over manual methods?

Digital inventory tracking uses tools such as barcode scanning, QR code scanning, RFID tracking, and IoT integration to offer real-time updates. These technologies not only boost efficiency but also improve accuracy, eliminating the errors often associated with manual processes. They also make it easier to monitor stock levels quickly and effectively.

On top of that, AI-powered systems take things a step further by analysing inventory patterns, forecasting demand, and automating reordering. This helps manufacturers save time and avoid common issues like stock shortages or excess inventory. By simplifying these processes, digital solutions free up businesses to concentrate on their primary activities while keeping inventory management sharp and reliable.