Digitising your factory floor is hard

- Steph Locke

- Archive

- November 9, 2021

Table of Contents

The process of digitising your factory floor is not an easy one but, with the help of our services, you can improve it. By focusing on areas that are easier to change, like back-office functions and support for growth, you are giving yourself a better opportunity to demonstrate value by modernising core processes.

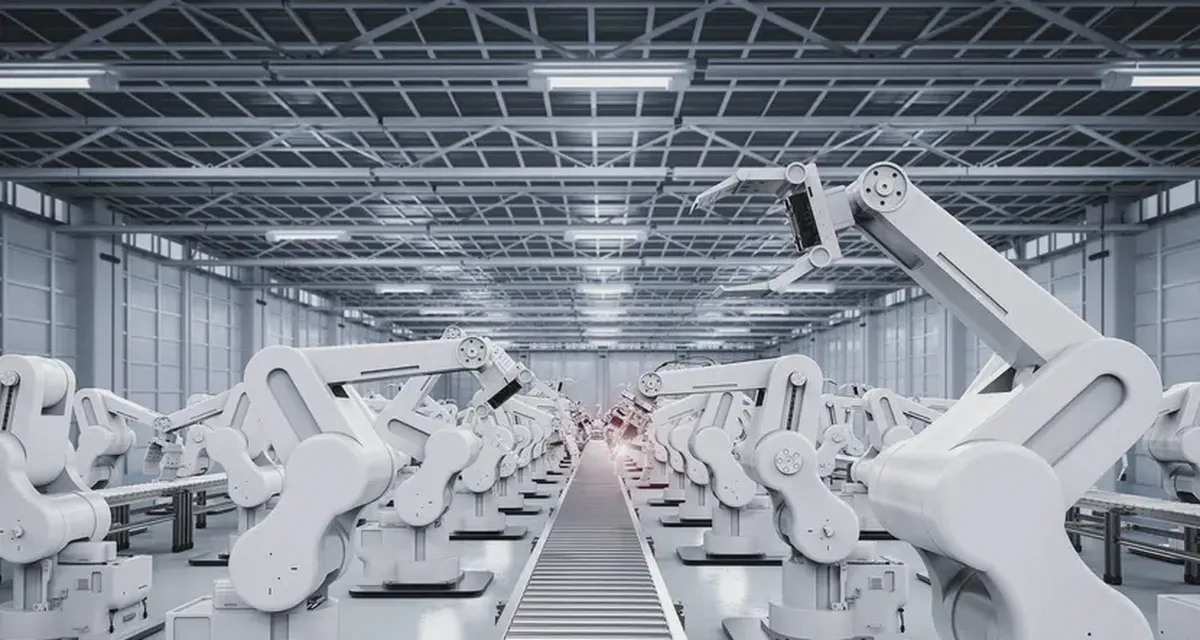

We realise that optimising your manufacturing processes is a top priority, but we also understand it’s not something that can be accomplished quickly. Industrial Internet of Things (IIoT), predictive maintenance, artificial intelligence-driven process control, robotics, and real-time data collection are all complicated, owing to the different production equipment, configurations, and procedures manufacturers use. Most of these things don’t just involve “plug and play” solutions at this time; they also include significant service and implementation costs as well as personnel re-skilling efforts.

Getting there takes time, money, and change management. Getting it wrong creates panic about ransomware, system takeovers, and more.

So it’s not easy and the risks are large. You need to do it but we try to take a pragmatic and incremental approach to achieve this goal. To that end, we believe you should start small and in lower risk areas.

For example, automating your inventory management is a great place to start. It’s usually pretty well defined and fits into existing systems and processes relatively easily.

The next step might be looking at the configuration of assets on your factory floor. The software that manages these devices has often been around for years now but it just sits there doing nothing other than taking up space on hard drives or being lost altogether.

By adding this layer you can improve efficiencies meaningfully without massive capital expenditure required upfront. You also reduce operational risk by ensuring machines are configured correctly before they go away for maintenance. This is instead of removing them from service, only to have no spares available when something breaks, leading to an expensive engineer call out!

We also place a lot of emphasis on enhancing your core operational procedures to expand your business with your existing hard-to-replace personnel in finance, purchasing, planning, and other areas. Using technologies like AI, Robotic Process Automation (RPA), and no-code methods allows you to show the value of improving processes at low cost and with minimal investment. It also aids in the development of smaller technical projects intended to improve security and compliance efforts so you can develop the essential processes and trust necessary to address your larger factory floor problem.

All of this grows your capability and your business case for achieving your top priorities.

Our GoSmarter production assistant aligns with this approach of smaller use-case-driven technology adoption to foster capacity and appetite. You can address minor challenges with a pay as you use, configurable solution that fits into your systems without requiring any cloud or IT knowledge. You continue to develop while gaining the essential skills for a sweeping factory floor transformation.

When you try to digitise the factory floor all at once, it’s difficult. There is no silver-bullet technology that may be effortlessly deployed in a company without first having met all of the prerequisites. Data savviness, cybersecurity, and compliance expertise are all required for digitising your factory floor, as well as a workforce capable of comprehending and valuing the modifications to their schedules. Take a step-by-step approach that addresses these crucial areas to reduce the risk of your plan not delivering value fast enough.