The Complete Guide to Streamlining Metal Fabrication Operations

- Steph Locke

- Blog , Learning

- December 8, 2025

Table of Contents

Metal fabrication in the UK is crucial for industries like construction and aerospace but often faces inefficiencies that hurt profits and delay projects. The key to solving these issues lies in improving workflows, reducing waste, and using technology effectively. Here’s what you need to know:

- What Streamlining Means: It’s about cutting delays, boosting productivity, and reducing material waste without lowering quality. This leads to faster production, cost savings, and better client trust.

- AI and Automation: Technologies like AI-driven scheduling, predictive maintenance, and automated material handling are transforming fabrication. They minimise downtime, optimise workflows, and reduce errors.

- Workflow Analysis: Mapping processes like quoting, cutting, welding, and finishing helps identify bottlenecks, delays, and inefficiencies.

- KPIs for Success: Metrics like OEE (Overall Equipment Effectiveness), scrap rates, lead times, and energy use help measure and improve performance.

- Upskilling Workforce: Training workers in data literacy and automation ensures they can effectively use new tools.

- Continuous Improvement: Using AI and frameworks like PDCA (Plan-Do-Check-Act) helps refine processes over time.

Analysing Current Workflows and Identifying Bottlenecks

Before introducing new technologies or refining processes, it’s crucial for fabricators to have a clear understanding of how their current operations run. Many metal fabrication shops across the UK rely heavily on long-standing practices and the expertise of their workforce rather than formalised processes. This can make it harder to pinpoint where time, resources, or money are being wasted. By conducting a thorough analysis, inefficiencies can be uncovered, paving the way for meaningful change.

Mapping Metal Fabrication Workflows

The typical metal fabrication process in the UK follows a sequence of steps: quoting and estimating, design, nesting, cutting, forming, joining, finishing, inspection, and finally, dispatch.

It all begins with quoting and estimating, where customer requirements are reviewed, materials are priced, and labour hours are calculated. Once the job is confirmed, it moves to the engineering and design stage. Here, CAD drawings are created or adjusted to suit manufacturing needs.

Next comes nesting, where cutting patterns are digitally optimised to minimise material waste. This involves arranging sheet metal layouts to extract the maximum number of parts from each sheet. These optimised patterns are then fed into cutting machines - such as laser cutters, plasma cutters, or waterjets - that transform flat sheets into precise components.

After cutting, the parts proceed to forming and bending, where press brakes shape them into three-dimensional forms. This stage often requires skilled operators who can account for material properties like springback. Welding and joining follow, assembling the components into larger structures or final products. This step demands precision and rigorous quality checks to ensure the integrity of the assembly.

The journey continues with finishing processes, which may include grinding, deburring, powder coating, or galvanising, depending on customer requirements. Finally, products undergo quality inspection and are prepared for dispatch to ensure they meet all standards before being shipped.

However, between these stages, components often sit idle, waiting for the next operation. Moving parts between workstations takes time and can increase the risk of damage or misplacement. These transition points often become bottlenecks that disrupt the flow. By mapping the entire workflow, fabricators can lay the groundwork for analysing delays using value stream mapping.

Using Value Stream Mapping to Identify Inefficiencies

Value stream mapping provides a clear visual breakdown of every step in the fabrication process, helping to separate value-adding activities from those that don’t contribute to the final product. This involves walking through the shop floor, stopwatch in hand, to measure how long each operation takes and how much time parts spend waiting between stages.

To start, select a representative product or job type that moves through the entire workflow. Track this batch from the quoting stage right through to dispatch, recording key timings - such as processing, waiting, moving, and inspection times. Often, this exercise reveals that active processing accounts for only a small fraction of the total lead time, with delays from waiting and moving proving to be major contributors.

Common sources of inefficiency tend to surface during this process. Overproduction, for instance, can occur when shops produce more parts than immediately needed to maximise machine usage, leaving excess inventory that ties up resources and space. Poor shop layouts can result in excessive material handling, forcing parts to travel unnecessarily long distances. Quality issues that require rework not only disrupt schedules but also increase labour costs.

One of the most pressing issues is often waiting time. Whether it’s parts queuing for the next operation or delays in material deliveries, these hold-ups can significantly extend production timelines. By visually mapping these delays, fabricators can identify where attention is most urgently needed.

The value stream map should also highlight how information flows through the organisation. For example, if job specifications and instructions are manually re-entered at each stage, it can lead to errors and slow down communication. These inefficiencies can then be quantified to help shape key performance indicators (KPIs) for ongoing improvement efforts.

Establishing Baseline KPIs

To measure and improve operational performance, fabricators need to establish key metrics. For UK metal fabricators, several KPIs are particularly useful for identifying inefficiencies and boosting profitability. One of the most comprehensive metrics is Overall Equipment Effectiveness (OEE), which combines availability, performance, and quality into a single measure. While high OEE scores are the hallmark of top-tier operations, many shops have room to improve.

OEE is broken down into three components:

- Availability: Tracks the percentage of scheduled machine time that is actually productive, accounting for factors like breakdowns and changeovers.

- Performance: Compares actual cycle times to ideal cycle times.

- Quality: Measures the percentage of parts produced correctly on the first attempt.

Scrap rates are another critical metric, particularly given the fluctuating cost of steel in the UK. Even small reductions in scrap rates can lead to noticeable savings over time.

Lead time, which covers the entire duration from order receipt to dispatch, is another vital measure. Analysing lead times by product type or job complexity can help pinpoint stages prone to delays. Comparing quoted lead times with actual delivery times can also highlight areas where estimates may be overly optimistic.

The first-time-through (FTT) rate measures how often jobs are completed without requiring rework or corrections. A low FTT rate can indicate issues with processes, training, or specifications, all of which can increase costs and disrupt schedules.

Energy consumption is becoming an increasingly important KPI, especially with the high electricity prices in the UK. Many modern machines, such as CNC cutters and welding equipment, come with built-in monitoring systems to track energy use. Establishing a baseline for energy consumption can help fabricators spot inefficient equipment and identify opportunities for savings through process improvements or equipment upgrades.

Accurate data collection is crucial for tracking these metrics. Many modern machines can output production data digitally, reducing the risk of errors. For older equipment, retrofitting sensors or implementing operator-reported systems can provide useful benchmarks, though with slightly less precision.

Consistency is essential. Define standardised methods for measuring each KPI, train staff on proper data collection, and review the numbers regularly. Routine analysis not only helps identify emerging problems early but also ensures that decisions are based on solid data rather than guesswork.

Using AI for Workflow Optimisation

Once workflows are mapped out and baseline metrics are established, fabricators can take the next step by implementing AI-powered systems. These systems analyse production data to spot inefficiencies and suggest actionable adjustments. This proactive approach helps fabricators tackle issues before they become significant roadblocks.

AI excels at consolidating data from various sources within fabrication shops, making it easier to uncover trends and anticipate potential inefficiencies. A standout use of AI in metal fabrication is its ability to improve job scheduling.

AI-Driven Job Scheduling

AI-powered job scheduling uses production data to determine the best sequence of jobs, addressing inefficiencies and refining schedules for better results [3][4] - link no longer works. Unlike manual scheduling, which often misses critical factors that impact production flow, these systems leverage accurate data from ERP systems and PLCs. This enables them to organise jobs based on machine capacity and material lead times, creating a smoother workflow [1][4] - link no longer works.

Implementing AI in Your Fabrication Operations

To get started with AI, integrate scheduling tools into your existing ERP and PLC systems. Automated data collection methods, such as RFID or AI-enabled vision systems, can provide the necessary data without requiring a complete infrastructure overhaul [2][4] - link no longer works.

How GoSmarter Supports AI-Powered Optimisation

GoSmarter

GoSmarter offers a platform designed to simplify production processes by working seamlessly with your existing systems. Its AI-driven tools help with compliance, streamline inventory management, and improve production planning by pulling all relevant data into one place. With a user-friendly interface, responsive customer support, and flexible pricing options (including free and pay-as-you-go plans), GoSmarter makes it easy for fabricators to adopt AI-driven scheduling with minimal disruption to their operations.

Integrating Automation and Digital Workflows

Automation and digital tools are transforming fabrication by replacing time-consuming manual tasks with efficient, interconnected systems that link machines, software, and operators. The result? Smoother processes and higher productivity.

Key Automation Technologies for Fabrication

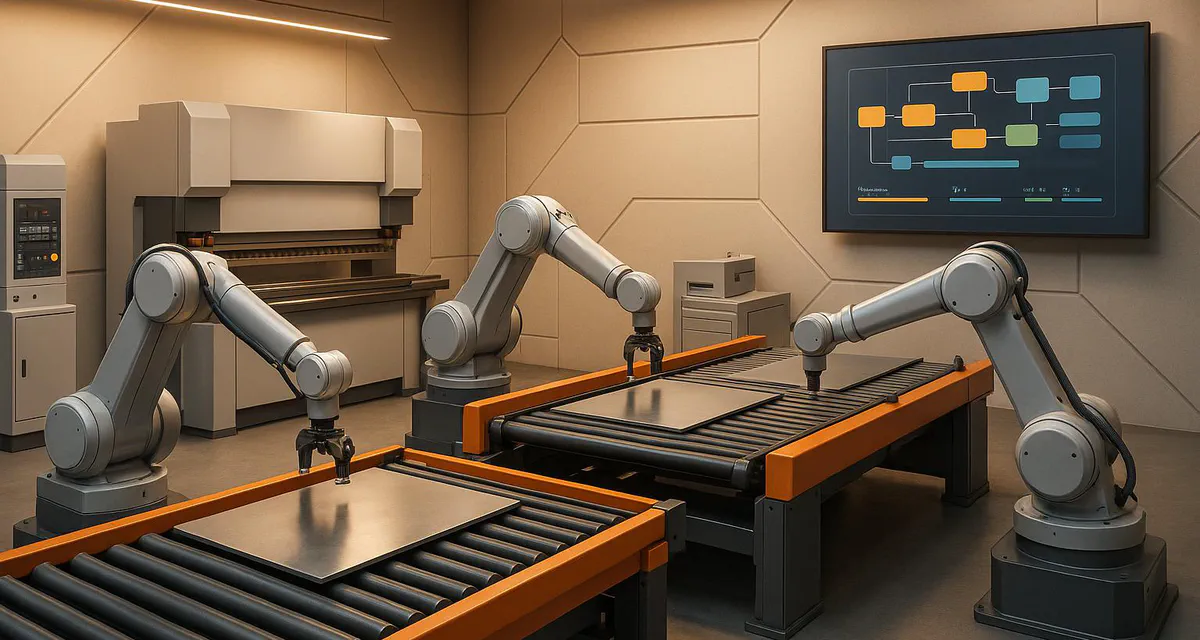

Robotic welding systems are now within reach for fabricators of all sizes. These systems handle repetitive welding tasks with precision, freeing up skilled welders to focus on more intricate work that requires human expertise. Modern robotic welders can be programmed to handle various joint configurations and material thicknesses, offering flexibility alongside reliability.

Meanwhile, CNC automation paired with auto-nesting software is revolutionising material usage. By calculating the most efficient arrangement of parts on sheet metal, this software reduces waste and accelerates programming. Instead of manually planning each cut, operators simply load part files, and the software does the rest - saving time and cutting material costs.

Automated material handling systems are another game-changer, eliminating delays in moving materials between workstations. Conveyor systems, automated storage and retrieval systems (AS/RS), and robotic loaders keep production lines flowing without the need for manual intervention. This is especially valuable in high-volume operations, where material movement can otherwise eat up a significant amount of labour hours.

Together, these technologies set the stage for a fully connected digital workflow.

Digital Workflow Integration

A critical component of modern fabrication, Manufacturing Execution Systems (MES), bridges the gap between the shop floor and the office. These systems provide real-time updates on work orders and machine statuses, ensuring that everyone has access to the latest information on production progress, bottlenecks, and deadlines.

CAD/CAM software integration is another leap forward, removing the need for manual programming that can slow production. When design files are directly integrated into machining software, cutting paths and tool selections are automatically generated. This reduces programming time from hours to minutes and minimises errors caused by manual input.

Digital work instructions further streamline processes by updating automatically when engineering changes occur. This ensures that operators are always working with the most current specifications, reducing errors and confusion.

Another major advantage of digital workflows is improved traceability. Every step, from the receipt of raw materials to the final inspection, is recorded in the system. This creates a detailed audit trail that is essential for maintaining quality standards and meeting compliance requirements - particularly in industries like aerospace and medical device manufacturing.

Connecting Automation with AI and Data

Taking automation a step further, integrating AI allows for continuous optimisation of production. Sensors embedded in CNC machines, welding systems, and material handling equipment monitor performance in real time, enabling predictive maintenance and enhanced quality control.

Machine vision systems powered by AI inspect parts during production, catching defects before they move to the next stage. These systems capture images of welds, cuts, or assemblies and compare them against predefined quality standards. If a deviation is detected, the system immediately alerts operators or halts production to avoid further waste. Over time, the AI refines its ability to distinguish acceptable variations from actual defects, improving inspection accuracy and production quality.

Dynamic production becomes achievable when automation systems are paired with AI-driven scheduling tools. Real-time data from machines allows for automatic rerouting of work and resource balancing, preventing idle time and ensuring maximum efficiency.

Environmental factors like temperature and humidity can also impact metal fabrication, affecting cutting precision and weld quality. By using sensors to monitor these variables, fabricators can adjust machine parameters as needed, maintaining consistent quality and reducing rework.

Platforms like GoSmarter exemplify how automation and AI can work together. These systems unify production data, inventory levels, and compliance requirements into a single interface. This eliminates the need to juggle multiple applications, saves time, and ensures all systems operate from the same accurate data.

Centralising data management also simplifies governance. Automation systems automatically feed information - such as production quantities and material usage - into central platforms. This eliminates the risk of transcription errors and provides real-time visibility into operations, reducing administrative overhead and improving decision-making efficiency.

Ensuring Governance, Skills, and Continuous Improvement

Streamlining metal fabrication isn’t just about installing advanced technologies. It’s about building systems that work seamlessly with skilled teams to ensure lasting progress. Without strong data governance, a capable workforce, and a genuine focus on continuous improvement, even the best automation or AI tools can fall short.

Data Governance and Compliance in the UK

As fabrication becomes increasingly digital, managing data responsibly is critical. Every sensor reading, production log, and quality check generates data that must be securely stored, organised, and used in line with UK and European regulations.

Take the UK GDPR, for example. This regulation applies to any fabrication business handling personal data, whether it’s employee records, customer information, or supplier details. Compliance involves collecting data lawfully, safeguarding it, and ensuring it’s only retained for as long as necessary. This includes implementing access controls to restrict sensitive information to authorised personnel and establishing clear protocols for securely deleting data that’s no longer required.

In regulated sectors like aerospace or medical manufacturing, additional rules come into play. For instance, fabricators must adhere to the Medical Device Regulation (MDR) for components used in healthcare or meet stringent aerospace standards for aviation parts. Traceability and sector-specific compliance are non-negotiable.

To ensure effective data governance, start by assigning clear responsibility. Whether it’s a quality manager, an operations director, or a dedicated data officer, someone must oversee data practices. This includes ensuring consistent data collection, maintaining accurate records, and conducting regular audits to check compliance.

Documented data retention policies are essential. While production data might need storing for years to support warranty claims or regulatory audits, other information can be archived or deleted sooner. Automated systems can help by identifying outdated records, reducing the manual effort required.

Security is another key focus. Beyond basic passwords, consider role-based access controls to limit data access to relevant employees. Regular backups and encryption protect data from loss or breaches, and for cloud-based systems, ensure your provider complies with UK data protection laws and stores data in approved locations.

Modern digital systems also provide transparency by automatically logging who accessed which data and when. This not only satisfies regulatory requirements but also helps quickly resolve discrepancies if they arise.

Upskilling the Workforce for AI and Automation

The shift to AI and automation means the workforce needs new skills to operate, monitor, and optimise these advanced systems. Technology alone won’t drive transformation - skilled, confident people are essential.

Data literacy is becoming as important as traditional machining skills. Workers need hands-on training to understand AI alerts and interpret dashboard trends. Instead of abstract theory, training should focus on practical, day-to-day scenarios - like responding to predictive maintenance alerts, adjusting machine settings based on sensor feedback, or verifying AI-driven quality checks.

Learning to work alongside AI is another crucial skill. Operators must learn to trust AI recommendations while still applying critical thinking. For example, AI might suggest an ideal cutting path or flag a potential issue, but human judgement is vital for understanding context, handling exceptions, and making the final call. Training should highlight this collaboration, showing employees how AI complements their expertise rather than replacing it.

As automation takes over repetitive tasks, skilled workers can focus on more complex and rewarding activities. Welders, for instance, can move from basic joints to intricate assemblies requiring precision and craftsmanship. CNC programmers can shift their focus from manual coding to optimising workflows and troubleshooting. These changes require careful planning - identify which roles will evolve and provide the training needed for a smooth transition.

Some fabricators are introducing internal apprenticeship programmes that combine traditional metalworking skills with digital competencies. New hires learn welding and machining alongside data analysis and automation system operation, preparing them for the modern shop floor.

As operations grow more advanced, hiring specialised roles becomes necessary. Automation engineers manage robotic systems, while data analysts extract insights from production data to drive improvements. These roles don’t replace traditional fabricators - they enhance the team’s capabilities.

It’s also important to address resistance to change. Some workers may worry that automation threatens their jobs. Clear communication is key - explain how technology creates opportunities for skill development and career growth. Involve experienced workers in implementing new systems, drawing on their practical knowledge to make these systems effective and user-friendly.

When skilled teams work hand-in-hand with data-driven insights, operations can continuously refine and improve.

Embedding Continuous Improvement with AI

Continuous improvement isn’t a one-time effort - it’s an ongoing process of making operations better every day. AI and automation provide the data and insights needed to support frameworks like PDCA (Plan-Do-Check-Act).

The Plan phase starts by pinpointing areas for improvement. AI excels at analysing production data to uncover patterns that might go unnoticed. For example, it might reveal that certain machines underperform during specific shifts or that particular materials result in higher scrap rates. These insights help prioritise issues that have the biggest impact on efficiency, quality, or cost.

In the Do phase, changes are implemented on a small scale to test their effectiveness. This could mean adjusting machine settings, reorganising workflows, or introducing new procedures. AI-driven simulations can predict outcomes before changes are made, reducing the risk of disruption.

The Check phase evaluates results using data. Compare metrics before and after the change - has productivity improved? Has waste decreased? AI systems can track these metrics automatically, generating reports that make it easy to assess whether the changes worked.

Finally, the Act phase involves standardising successful changes across the operation or refining strategies that didn’t deliver the expected results. Documenting lessons learned ensures that mistakes aren’t repeated and helps new employees understand why processes are designed a certain way.

Reducing waste is a key focus in metal fabrication. AI can identify inefficiencies that aren’t immediately obvious, like excess material usage, idle energy consumption, or time wasted on poorly sequenced tasks. By quantifying these losses, fabricators can prioritise improvements with the greatest impact.

Predictive maintenance also plays a role in continuous improvement by minimising downtime caused by unexpected equipment failures.

Creating a culture of improvement is essential. Encourage employees at all levels to share ideas for better processes. Shop floor workers often have valuable insights into what’s working and what isn’t. Establish channels for them to voice suggestions and act on their feedback. When employees see their ideas leading to real changes, they’re more engaged and invested in the process.

Regular review meetings help keep improvement efforts on track. Bring together key stakeholders monthly or quarterly to evaluate progress, address challenges, and plan next steps. Use data dashboards to keep discussions focused on specific metrics and trends, avoiding vague or unproductive conversations.

AI enables a shift towards adaptive manufacturing, where systems continuously optimise themselves in real time. Production schedules can adjust automatically to accommodate urgent orders or material shortages. Machine settings can fine-tune themselves as tools wear down, ensuring consistent quality. This level of responsiveness transforms continuous improvement from a series of projects into a core feature of the operation.

The combination of strong governance, skilled teams, and a commitment to constant improvement lays the groundwork for lasting success. Technology provides the tools, but it’s the people and processes behind it that ultimately determine the outcome.

Conclusion

Improving metal fabrication operations is about creating systems that are efficient, reduce waste, and maintain high-quality standards. By addressing inefficiencies through well-defined workflows and measurable KPIs, businesses can lay the groundwork for long-term progress. Once current workflows are thoroughly analysed, the next logical step is to implement streamlined processes that deliver tangible, lasting results.

As discussed earlier, AI and automation play a pivotal role in this transformation. These technologies process production data into actionable insights and handle repetitive tasks with precision and consistency. When integrated thoughtfully, they work together seamlessly, forming an operation where every component complements the others.

However, relying solely on technology won’t lead to success. Robust data governance ensures compliance with UK GDPR and industry-specific regulations while safeguarding data security and traceability - both critical for modern fabrication. Equally important is investing in the workforce. Upskilling employees allows them to blend traditional craftsmanship with new digital skills, enabling them to collaborate effectively with AI and automation. Adopting frameworks like PDCA (Plan-Do-Check-Act) ensures continuous improvement by using data-driven insights to refine processes over time.

Success in metal fabrication doesn’t depend on having the largest budget or the most advanced tools. It’s about taking a systematic approach - setting clear goals, making thoughtful changes, and fostering a culture where technology and skilled professionals work hand in hand.

In an industry that evolves rapidly, being proactive is no longer optional. By embracing systematic implementation and committing to ongoing refinement, businesses can create operations that are not only efficient and profitable but also resilient enough to tackle future challenges.

FAQs

How can metal fabrication businesses in the UK adopt AI and automation technologies without disrupting their current workflows?

To make the most of AI and automation, UK metal fabrication businesses should start by evaluating their current workflows and pinpointing where these technologies can make the biggest difference. Areas like robotic welding or predictive maintenance are often great starting points. Tackling smaller, clearly defined projects first can minimise disruption and give teams time to adjust to the changes.

It’s also crucial to focus on training and upskilling employees so they feel equipped to handle tools like robotics and other digital systems. Partnering with supply chain collaborators and looking into government grants or leasing options can help ease financial pressures. By introducing these technologies step by step, businesses can keep operations steady while improving processes gradually.

How can I identify and resolve bottlenecks in metal fabrication to boost efficiency?

To spot bottlenecks in metal fabrication, begin by digging into real-time data, carrying out process audits, and using visual inspections to uncover delays or inefficiencies. Once you’ve pinpointed the trouble spots, here’s how you can tackle them:

- Revamp workflows to make operations smoother and more efficient.

- Invest in better equipment to cut down on downtime.

- Automate repetitive tasks to speed up production and free up resources.

- Offer focused staff training to sharpen skills and minimise mistakes.

By addressing these issues, you can boost production speed, cut down on delays, and make your fabrication processes run more efficiently.

How can UK metal fabricators stay compliant with GDPR and industry regulations when adopting digital and automated systems?

To comply with UK GDPR while integrating new digital and automated systems, metal fabricators should prioritise a few key steps. Start by conducting thorough data protection impact assessments to identify and mitigate risks. Implement strong cybersecurity measures to safeguard sensitive information, and ensure all data processing aligns with GDPR principles. Transparency is crucial - clearly communicate with employees and clients about how their data is used, obtain the necessary consents, and, if applicable, appoint a Data Protection Officer to oversee compliance.

When it comes to industry-specific regulations, such as welding standards or safety requirements, staying on top of these is equally important. Regular audits, comprehensive staff training, and strict adherence to standards like BS4872 or ISO safety guidelines can help maintain compliance. Partnering with legal and compliance professionals is a smart move to ensure that all regulatory boxes are ticked while seamlessly adopting advanced technologies.