How AI Transforms CRM for Metals Manufacturing

- Steph Locke

- Blog

- January 11, 2026

Table of Contents

AI is reshaping customer relationship management (CRM) in metals manufacturing by addressing long-standing issues like fragmented data, manual processes, and inconsistent customer experiences. Traditional tools such as spreadsheets and disconnected systems struggle to meet the complexities of the industry. AI-powered CRMs, using machine learning and real-time analytics, provide solutions that streamline operations, improve demand forecasting, automate repetitive tasks, and personalise customer interactions.

Key takeaways:

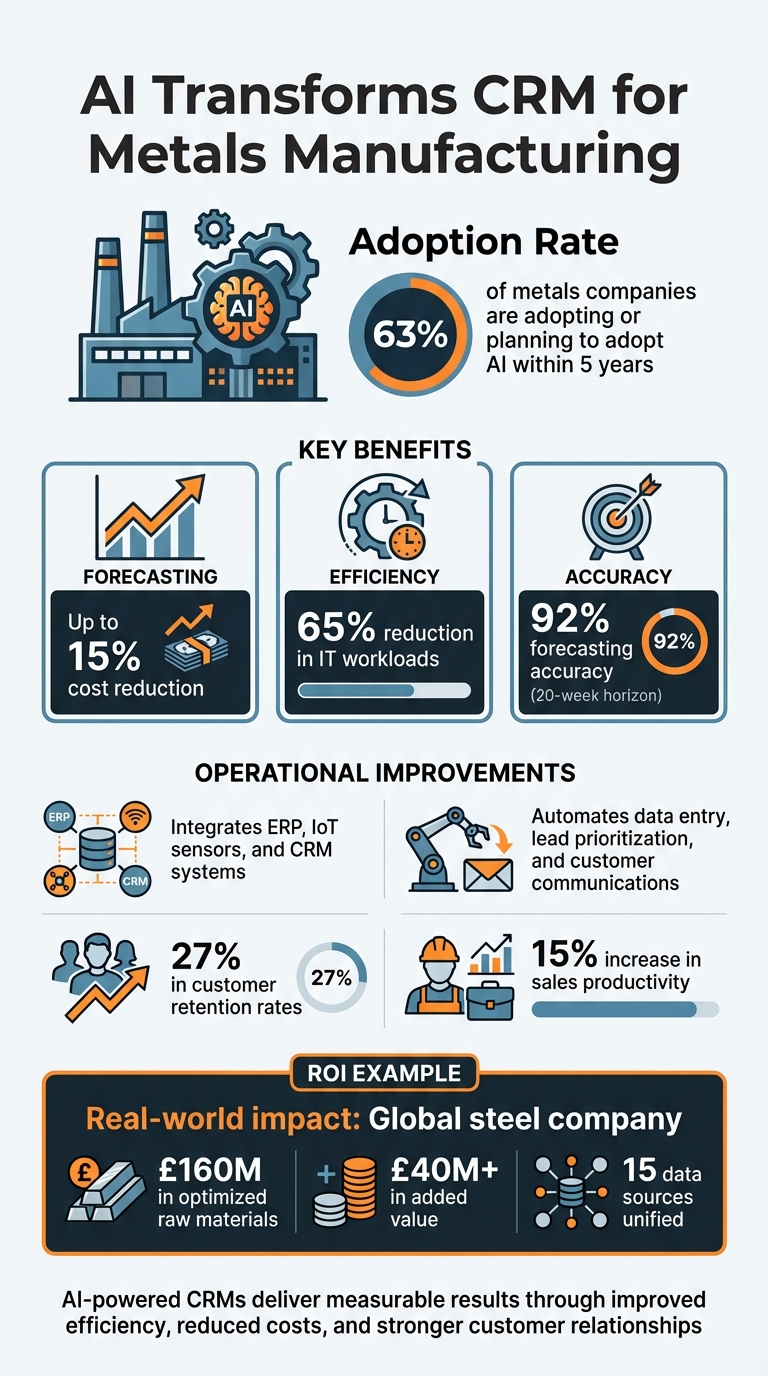

- 63% of metals companies are adopting or planning to adopt AI within five years.

- AI can improve forecasting accuracy, reduce costs by up to 15%, and cut IT workloads by 65%.

- It unifies data from ERP, IoT sensors, and CRM systems into a single view.

- AI tools automate tasks like data entry, lead prioritisation, and customer communications.

- Personalised experiences and predictive insights drive better customer retention and decision-making.

To integrate AI into your CRM:

- Assess your current systems and data readiness.

- Choose a CRM platform that integrates well with your existing tools.

- Start small with pilot programmes and focus on areas with high impact.

- Train your team and track performance metrics like lead accuracy and customer retention.

- Expand AI applications to other operations, such as inventory management and predictive maintenance.

AI-powered CRMs are no longer optional for metals manufacturers aiming to stay competitive. They deliver measurable results by improving efficiency, reducing costs, and strengthening customer relationships.

AI Impact on Metals Manufacturing CRM: Key Statistics and Benefits

Common CRM Challenges in Metals Manufacturing

Traditional CRM systems in the metals manufacturing sector often struggle with fragmentation, manual workflows, and disconnected data. These issues slow down operations, limit efficiency, and make it harder to meet customer expectations. Before introducing AI to overhaul your CRM, it’s essential to address these core challenges. Here’s why traditional CRM systems often fall short in this industry.

Disconnected Data and Limited Visibility

When vital data is spread across multiple systems - like ERP for production, standalone inventory tools, and isolated CRM platforms - keeping track of individual parts becomes a logistical nightmare, especially when production batches are split [11]. Instead of quick, actionable insights, quality interventions can stretch from minutes to months due to the lack of a unified view [11].

The financial repercussions are hard to ignore. Fragmented data processes can cost businesses anywhere between 15% and 25% of their total revenue [13]. Tony Barnes, Principal and Microsoft Cloud Solutions Leader at Crowe, captures the problem well:

Metals companies with data stored in multiple systems might experience setbacks if they attempt to move into [AI] prematurely. When data is pulled in from several different sources… the process of using AI can become complex [3].

Disconnected data doesn’t just slow down decision-making - it also creates inefficiencies in production schedules, inflates inventory costs, and hampers quality control [10]. Without a complete and accurate picture, decisions are based on incomplete information, which often leads to costly errors.

Manual Processes and Administrative Bottlenecks

In addition to scattered data, manual processes further undermine CRM efficiency in metals manufacturing. Manual data entry remains a significant drain on productivity. Sales teams, for instance, often prioritise closing deals over updating CRM records, resulting in incomplete or outdated customer information.

Another bottleneck comes from manually handling supplier invoices and compliance documents like Mill Test Reports (MTRs). These tasks are not only time-consuming but also prone to errors [9]. Such delays can create communication gaps, making it harder for sales teams to notify customers of production disruptions or shipping delays in a timely manner.

Dave Turbide from Quickbase sums up the issue perfectly:

If you have one clock, you know the time. If you have two clocks, you can’t be sure what time it really is [12].

This “two clocks” problem often arises when sales teams rely on spreadsheets while production teams depend on ERP systems. The result? Conflicting information about lead times and material availability. Without integrated systems, providing accurate “available-to-promise” (ATP) or “capable-to-promise” (CTP) dates becomes nearly impossible, leaving customers frustrated and uncertain.

Inconsistent Customer Experience

Fragmented systems also create silos between marketing, sales, customer service, and production. Even when manufacturing runs smoothly, poor integration with customer-facing teams can lead to miscommunication about order updates and delivery timelines. This is particularly concerning when 60% of product selection happens before customers even reach out to a company [14], and by 2025, 80% of the B2B buying process is expected to occur online [13].

The complexity of modern purchasing decisions further complicates matters. The percentage of buying decisions involving four or more stakeholders jumped from 47% in 2019 to 61% in 2021 [13]. Without a single, reliable source of information, it becomes nearly impossible to deliver consistent, personalised communication to all involved parties.

Real-time visibility is another missing piece. Sales teams often fail to flag production delays promptly, leading to missed deadlines and disappointed customers. These delays chip away at trust and increase the risk of customer churn. In an industry where 95% of manufacturing leaders agree that digital transformation is essential for future success [13], inconsistent customer experiences are a vulnerability that no company can afford. Solving these issues is the first step toward leveraging AI to enhance CRM systems effectively.

How AI Improves CRM for Metals Manufacturing

When it comes to tackling the challenges in your CRM - like scattered data, manual processes, and inconsistent customer experiences - AI steps in with practical solutions. Tools like GoSmarter use AI to bring data together and simplify CRM workflows, helping metals manufacturers run operations more efficiently. AI is reshaping how businesses engage with customers, predict demand, and manage day-to-day tasks. The shift is already happening: 63% of metals companies are either using AI now or plan to adopt it within the next five years [3]. These tools don’t just identify problems - they deliver measurable results.

Real-Time Data Analysis and Demand Forecasting

AI is a powerful tool for addressing fragmented data and manual bottlenecks. It consolidates information from multiple sources - like CRM, ERP, Manufacturing Execution Systems (MES), IoT sensors, and even spreadsheets - into a single, unified system. Machine learning then analyses this data to uncover patterns that are often too complex for human analysis, such as seasonal trends, competitor pricing changes, or historical sales insights. Unlike traditional forecasting methods that take days to adjust, AI provides real-time updates that account for sudden market shifts, geopolitical factors like tariffs, or unexpected changes in distributor orders [16].

For example, a global steel company with annual revenue exceeding £28 billion implemented AI to unify 15 data sources and 23 models. This system enabled a 20-week forecasting horizon with 92% accuracy, optimised £160 million worth of raw materials, and generated over £40 million in added value [15].

Jordan Joltes, CEO of TruSummit Solutions, offers a practical perspective for businesses unsure about their data readiness:

The reality of getting started with AI is no one’s data is ever ready. We encourage leaders to shift their mindset from ‘How do I fix my data?’ to ‘Where can I create momentum?’ [17]

Rather than waiting for perfect data, focus on specific workflows where AI can make an immediate impact. For instance, AI can enhance quoting accuracy or forecast demand for key products. AI systems can also monitor data streams to flag risks, like inventory shortages, or suggest production changes based on demand signals, enabling proactive decisions [17].

Better Customer Engagement

AI takes customer engagement to the next level by enabling personalised interactions on a large scale. By analysing data such as online behaviour, social media activity, and purchase history, AI tailors product recommendations and content for each customer [19]. AI-powered chatbots and virtual assistants handle routine queries instantly, offering 24/7 support without human involvement [2][19].

Connecting IoT data to CRM systems can detect equipment issues before customers even notice, triggering timely maintenance and automated service requests [19][20]. Sentiment analysis tools further enhance engagement by monitoring social media and customer feedback in real time, helping companies address concerns quickly and improve retention rates [2][6]. Generative AI also supports sales teams by drafting personalised emails and offering negotiation tips based on historical customer interactions [1][8].

Dr. Andy Moore, Chief Data Officer at Bentley Motors, highlights the importance of trust in AI adoption:

Removing fear and helping everyone understand what is and isn’t possible will lead to more valuable use cases, with the business and technical stakeholders working in partnership to drive innovation [5].

To build customer trust, it’s essential to establish ethical practices, such as data masking for sensitive information and transparency about AI-generated outputs. This approach ensures long-term success [5].

Automation of Repetitive Tasks

While AI enhances customer interactions, it also boosts efficiency by automating repetitive tasks. It takes over time-consuming activities like data entry, real-time updates to customer records, and syncing information across applications [2][1]. AI-powered tools manage communication and scheduling, from organising appointments to sending reminders. Generative AI even drafts personalised emails, follow-ups, and proposals using historical data [2][7][20].

AI also streamlines lead management by categorising customer interactions, prioritising high-potential leads, and capturing data from web forms or chatbots [2][7]. It simplifies reporting by generating sales insights, performance metrics, and custom dashboards, reducing the manual effort required for business intelligence [2][7]. Even call recording tools now summarise key points and action items automatically [2][1].

The impact is undeniable. AI-integrated CRM systems can cut IT administrative workloads by up to 65% [1] and increase sales productivity by as much as 15% [21]. Businesses that maximise their CRM capabilities have seen customer retention rates climb by as much as 27% [21].

William Sigsworth, Head of SEO at Pipedrive, sums up the transformation:

Integrating AI technology into your CRM is a game-changer, pushing productivity and efficiency beyond traditional processing speeds, manual workflows and limited insights [2].

Start small with affordable AI tools that deliver big results, like virtual assistants for finance or team communication [3]. Before diving in, prioritise data quality - poor data can undermine the ROI of automation [7][3]. Focus on the customer journeys where automation will have the greatest impact on your bottom line [1].

How to Integrate AI into Your CRM System

Bringing AI into your CRM system isn’t something you can rush - it’s a step-by-step process that builds on what you already have. With only 28% of UK manufacturers fully digitised [23], most businesses are starting from a similar baseline. The process involves educating your team, creating a solid plan, and then deploying AI while continuously refining it. This phased approach ensures a smooth connection between your strategic goals and the technical implementation.

Evaluate Your Current CRM Setup

Before diving into AI tools, take a closer look at what you already have. Start by assessing your data maturity. Map out all your data sources - ERP systems, Manufacturing Execution Systems (MES), and IoT sensors [23]. This helps you identify where your data is stored and spot any gaps in integration.

Next, check if your CRM can handle AI. Does it support API integrations? Are there AI add-ons you can easily plug in? If not, middleware tools like Zapier can help bridge the gap [2].

Pinpoint areas where manual tasks are slowing things down. These are great opportunities for AI to step in [2]. Align AI projects with stakeholder needs and prioritise initiatives that offer high returns for minimal cost. A simple matrix comparing ROI against implementation costs can help you focus on the most impactful projects first [3]. This groundwork ensures AI will enhance customer insights and streamline operations.

Tony Barnes, Principal at Crowe, offers a clear warning for business leaders:

Choosing the wrong tool or taking an uncalculated approach can be costly. Metals leaders can achieve greater success and benefits by approaching AI implementation in a series of intentional stages. [3]

Set SMART goals - specific, measurable, achievable, relevant, and time-bound. For example, aim to cut down scrap material by 20% within six months [23].

Select an AI-Powered CRM Platform

The right CRM platform should fit your operational needs like a glove. For metals manufacturers, integration with backend ERP systems is crucial. You need a system that unifies customer data, inventory, billing, and fulfilment [24]. Look for platforms that consolidate data from multiple sources and help automate compliance tasks, which are especially important in metals manufacturing.

You can also look for “bolt-ons” to new or existing solutions. For example, GoSmarter, a platform designed specifically for metals manufacturers offers AI tools for managing mill certificates, inventory, and compliance, all while integrating seamlessly with your existing systems. Plus, its pay-as-you-go pricing model means you can scale up without hefty upfront costs.

Security is another critical factor. Choose platforms that offer features like data masking and “zero data retention” policies for external AI models [5]. Ensure the system can handle both structured and unstructured data and supports either real-time or batch processing, depending on your needs [5].

Start small with affordable AI tools that deliver big results, like AI assistants for back-office tasks, before moving on to more complex AI applications [3]. Currently, 46% of business owners are already using AI in their CRM systems [2], and the trend is growing as more companies realise the advantages of unified ERP/CRM solutions over disconnected data sources [3]. Once you’ve chosen your platform, it’s time to deploy AI and prepare your team for success.

Deploy AI and Train Your Team

Begin with a pilot programme. Assign a team to test the AI tool against your SMART goals over a set period - typically a few weeks to two months [2]. This trial phase helps you identify problems and fine-tune processes before rolling it out across the board.

Data harmonisation is key. AI thrives on clean, organised data, so make sure your systems - ERP, CRM, and any legacy platforms - are connected and aligned to create a single source of truth [5][8]. Without this, AI can’t deliver accurate insights.

Keep humans in the loop. AI should act as a helpful assistant, not a full replacement. This reduces risks like data bias or errors [5][8]. Address employee concerns early, as 73% of workers believe generative AI introduces new risks, and 61% admit they’re unsure how to handle trusted data or secure sensitive information [5].

Training your team is just as important as the technology itself. Offer short, focused sessions to help executives and employees understand AI basics. This builds confidence and reduces resistance [3]. Focus on developing seven essential AI skills: adaptability, data literacy, domain expertise, communication, prompt writing, analytical thinking, and technical know-how [5]. These skills will help your team leverage AI for better analytics and customer engagement.

Dr. Andy Moore, Chief Data Officer at Bentley Motors, highlights the importance of education:

Removing fear and helping everyone understand what is and isn’t possible will lead to more valuable use cases, with the business and technical stakeholders working in partnership to drive innovation. [5]

Consider forming a Centre of Excellence - a dedicated team to oversee AI initiatives, manage risks, ensure compliance, and guide the organisational changes needed for AI adoption [1]. This team will serve as your go-to resource for troubleshooting, scaling, and expanding AI capabilities across your business.

Tracking Performance and Making Improvements

Once you’ve rolled out your AI-powered CRM and trained your team to use it, the next step is all about tracking performance and making adjustments where needed. Keeping an eye on the right metrics ensures your AI investment pays off and helps you identify areas that could use some fine-tuning. With 63% of metals companies already using or planning to adopt AI within the next five years [3], staying on top of performance data can mean the difference between a successful implementation and one that falls flat.

Key Metrics to Track

Focus on metrics that directly affect your business outcomes. For sales and lead management, look at lead scoring accuracy, conversion rates, and the length of your sales cycle. These numbers reveal whether AI is helping to close deals faster and directing your team’s efforts towards the most valuable opportunities [2][5]. On the customer experience side, monitor customer retention rates, churn reduction, and response times for AI chatbot interactions [2][4].

Don’t overlook operational metrics either. Evaluate how well AI is improving efficiency by tracking demand forecasting accuracy, product yields, and throughput at bottlenecks [4][11]. Additionally, keep an eye on cost metrics like IT admin workload and annual support expenses. AI-powered CRMs can reduce IT admin workload by 65% and cut support costs by 30% [1].

| Metric Category | Key KPI to Track | AI Impact |

|---|---|---|

| Sales Performance | Lead scoring accuracy, sales cycle time | Faster deal closures and better resource use [2][5] |

| Customer Loyalty | Retention rate, churn reduction | More personalised interactions, repeat business [2][4] |

| Operational Efficiency | Demand forecasting accuracy, throughput | Improved inventory management, fewer bottlenecks [4][11] |

| Cost Savings | IT admin workload, support costs | Lower overheads [1] |

Armed with these metrics, you can use AI-driven insights to fine-tune your CRM strategy.

Using AI Data to Refine Your CRM Strategy

AI doesn’t just track metrics - it helps explain what’s driving them. For instance, if customer churn is linked to pricing rather than product reliability, AI insights can guide you to adjust your pricing strategy. Predictive models can also flag customers likely to need specific metals soon, giving your sales team a chance to proactively reach out [26][18]. One steel manufacturer, for example, saw a 15% improvement in sales forecasting accuracy after introducing predictive analytics into their CRM [26].

Dynamic pricing optimisation is another game-changer. By analysing historical data, AI can predict how customers will respond to price changes, letting you stay competitive without eroding your margins. Advanced segmentation tools also allow you to target specific regions or niche markets with customised campaigns [26]. For instance, a copper distributor boosted repeat business by 30% by using CRM data to personalise their outreach [26]. Additionally, integrating your CRM with internal systems like ERP, inventory, and delivery metrics provides a more comprehensive view of your operations, helping you identify strengths and address weaknesses.

These refinements create a solid foundation for expanding AI’s role in other areas of your business.

Expanding AI to Other Operations

Once your AI-powered CRM is delivering results, it’s time to think bigger. Start by integrating CRM data with your ERP, logistics systems, and factory sensors to break down data silos and create a unified operational view [5][8]. This integration can enhance inventory management, enabling predictive demand analysis to prevent stock shortages and optimise warehouse levels [2]. In production planning, AI can allocate resources in real time and identify bottlenecks, boosting output and reducing idle time [22].

Predictive maintenance is another logical step. By using sensors and digital twins - virtual replicas of physical assets - AI can predict equipment failures before they happen, cutting down on downtime and extending the lifespan of machinery [22][4]. AI also strengthens quality control by using computer vision to detect defects quickly and improve product consistency [22][4]. Even compliance and safety measures benefit, as AI monitors hazards in real time and ensures safety protocols are followed [22][4]. Start with smaller, low-cost AI tools to demonstrate value, then gradually scale up to more complex applications as your team becomes more confident [3].

Conclusion

AI-powered CRM systems have come a long way, transforming from simple contact databases into powerful tools that automate tasks, improve demand forecasting, and tailor customer interactions. By driving cost savings and boosting efficiency, these systems have become a cornerstone for metals manufacturers aiming to stay competitive. This evolution offers an opportunity to rethink and enhance how customer relationships are managed.

As Dominic Albarn, Partner – UK Microsoft Alliance Leader at KPMG in the UK, puts it:

Now is the perfect time to adopt a more intelligent CRM system – ideally incorporating the latest developments in AI – that can empower customer-facing staff with insights and decision tools whilst boosting operational efficiency [1].

To get started, evaluate your current CRM setup and pinpoint areas where AI can make an immediate impact, such as automating data entry or refining lead scoring. Prioritise high-quality data and ensure smooth integration with your existing systems. From there, expand AI’s role step by step - educate your team, create a clear roadmap, and test AI tools in smaller pilots before rolling them out across your operations [3].

With the metals manufacturing sector evolving at pace, AI-driven CRM systems present a clear opportunity to enhance efficiency, strengthen customer connections, and improve decision-making. Regularly monitor performance metrics and adapt your strategy to maximise AI’s potential. For those ready to explore these benefits, solutions like those from GoSmarter (https://gosmarter.ai) can be a valuable starting point. Begin with focused projects and build on those insights as you integrate AI across your operations.

FAQs

How does AI integrate data from different systems in metals manufacturing?

AI acts as a vital link, seamlessly connecting data from various systems that metals manufacturers rely on. These include ERP systems for production planning, MES platforms for shop-floor operations, PLM tools for product specifications, and CRM software for managing customer interactions. By integrating with these systems via APIs or other connections, AI not only gathers data but also standardises formats and units, making the information more usable. On top of that, it enhances records with predictive insights, like risk assessments or actionable recommendations for the next steps.

For metals manufacturers using GoSmarter, the platform takes this a step further by synchronising critical data - such as mill certificates, inventory levels, and compliance records - directly with the CRM. This integration eliminates the hassle of manual data entry, ensures data accuracy, and opens the door to smarter, data-driven decisions. For instance, it can recommend optimal pricing strategies or delivery schedules based on real-time production capacity. The result? Improved customer relationships and smoother, more efficient operations.

What are the first steps to integrate AI into a CRM system for metals manufacturing?

To bring AI into a CRM system for metals manufacturing, the first step is to set clear objectives. Think about how AI can make a difference in your processes - whether that’s automating mill certificate management, sharpening inventory insights, or anticipating customer demands. Having specific goals will help ensure the integration delivers real, measurable benefits.

The next step is to evaluate your current CRM system and data quality. Take a close look at the architecture and confirm that your customer and production data is accurate and well-organised. AI models thrive on reliable data, so ensuring its quality is critical for success.

Lastly, select AI tools that match your needs. Focus on solutions specifically designed for metals manufacturing, such as pre-built AI modules that simplify tasks like compliance checks or document handling. Platforms like GoSmarter provide tailored AI features, making it easier to integrate without the hassle of extensive customisation.

How does AI enhance customer retention in metals manufacturing?

AI-powered CRM systems are transforming how metals manufacturers understand and anticipate customer needs. By analysing data like buying patterns, service history, and production metrics, these systems can spot early warning signs of customer churn - such as smaller order volumes or more frequent support requests. Armed with these insights, businesses can take proactive measures, like offering personalised deals or scheduling service calls, to strengthen customer relationships.

These systems also handle repetitive tasks with ease. Whether it’s drafting follow-up emails, coordinating delivery schedules with production timelines, or generating mill certificates, AI ensures these tasks are completed efficiently. The result? Customers get accurate, timely information, leading to fewer delays and higher satisfaction.

GoSmarter’s AI-driven platform is specifically designed for the metals manufacturing industry. By blending CRM insights with real-time production data, it empowers manufacturers to offer tailored recommendations, simplify compliance processes, and deliver proactive support. This approach helps businesses across the UK market improve customer loyalty and retention.