AI Tools for Production Scheduling in Metals

- Steph Locke

- Blog

- January 10, 2026

Table of Contents

AI is transforming metals manufacturing by replacing manual processes with data-driven scheduling tools. These solutions improve efficiency, cut costs, and simplify compliance. Key highlights include:

- Efficiency Gains: Scheduling time reduced by up to 90%, with tools like GoSmarter enabling a 50% reduction in scrap rates.

- Cost Savings: AI-driven optimisation saves £17–£44 per metric tonne of steel, while predictive maintenance prevents costly downtime.

- Compliance Automation: Features like digital mill certificate management save over 120 hours annually.

- Energy Reduction: Spartan UK achieved a 24 kWh/tonne energy reduction and a 20% productivity boost using AI tools.

Top platforms include GoSmarter, EZIIL, Plataine, and more, each offering tailored features for metals production, from cutting optimisation to real-time scheduling. Whether you’re a small manufacturer or a large enterprise, AI tools can streamline operations and improve decision-making.

1. GoSmarter

GoSmarter

AI Automation Capabilities

GoSmarter’s production planning tools utilise Genetic Algorithms to analyse thousands of cutting combinations across order sets, helping manufacturers find the most efficient sequences for long products like rebar [9]. The Long Product Optimiser, introduced in July 2025, tackles the issue of leftover steel offcuts by matching open orders with available inventory. This results in cutting plans that significantly lower scrap rates. For instance, during testing at Midland Steel, scrap was reduced by an impressive 50% [2].

Another standout feature is the platform’s MillCert Reader, which uses AI to extract key information - like chemical composition and mechanical properties - from mill certificates. What would normally take hours of manual effort is now done in seconds, converting bulk documents into actionable data [8]. This automation saves production managers over 120 hours annually by eliminating the need to process and rename quality documentation manually [2].

Our AI tool saves hours every month by automatically pulling key data from mill certificates. It can rename documents in seconds which is a task that is usually painfully manual [8].

In addition to streamlining processes, GoSmarter strengthens compliance management with tailored features.

Metals-Specific Compliance Features

GoSmarter simplifies compliance by providing heat code traceability. It converts bulk mill certificates into single-page PDFs organised by heat code, ensuring every customer order is accompanied by the correct certification [2]. The platform also links material data with inventory records to maintain product lineage, ensuring that tasks like welding are carried out with the correct stock.

An AI-driven Emissions Calculator is another useful tool, allowing manufacturers to estimate carbon footprints based on variables like steel weight and production methods - whether using a Blast Furnace or an Electric Arc Furnace. This shifts sustainability reporting from being a reactive, cost-driven task to a more proactive form of environmental planning [7][2].

The platform also stands out for how effortlessly it integrates into existing workflows.

Integration and Scalability

GoSmarter is designed to fit seamlessly into current operations without causing disruptions [2]. Manufacturers can get started right away by uploading inventory and order spreadsheets in formats like Excel or CSV. The platform integrates easily with existing ERP systems and is built on Microsoft Azure Logic Apps, Power Automate, and Power BI, ensuring enterprise-grade security and smooth adoption for Microsoft 365 users [10].

It’s also built to grow alongside businesses, supporting multiple company locations under a single user account [6]. Additionally, GoSmarter offers a freemium model: basic tools for scrap management and simple calculations are free, while advanced features are available to registered users [7].

2. EZIIL

EZIIL

AI Automation Capabilities

EZIIL’s auto-scheduling engine takes the hassle out of planning by automatically organising projects based on available resources and capacity. This means it creates conflict-free schedules without the need for manual input, saving time and reducing errors [11][12]. Its MasterView dashboard enhances this process by offering auto-schedule suggestions, helping planners spot potential deadline risks and adjust workloads to avoid delays [13]. Aleksandr Mahhankov, Engineer Lead at Nordic Shelter, highlighted the platform’s efficiency, stating that for every hour spent using EZIIL’s Bill of Materials, eight hours were saved in procurement and 16 hours in production - a 24× return on time invested [11][13].

Beyond automation, EZIIL includes a visual scheduling feature tailored to metal fabrication workflows. With its drag-and-drop functionality, planners can arrange operations like cutting, welding, and painting in sequence. It even schedules tasks at the machine level, factoring in real-world conditions such as shifts, holidays, and downtime [11][12][13]. Rait Kalda, Chairman at Enefit Solutions, replaced daily Excel spreadsheets with EZIIL’s unified system, describing the transformation as:

EZIIL implementation is the most successful digitalisation project in our department. The whole team now works in one system, eliminating the need for multiple spreadsheets [11][13].

Real-Time Scheduling and Optimisation

EZIIL takes scheduling to the next level by updating plans in real time using data straight from the shop floor. This includes tracking hours worked versus planned and monitoring percentage completion [13]. Such transparency has enabled users to improve On-Time Delivery rates by at least 16%, thanks to capacity-aware scheduling and timely alerts [13]. The platform also supports mobile reporting, allowing shop floor workers to log hours and update job statuses in real time via tablets or smartphones. This constant flow of accurate data feeds directly into the auto-scheduling engine, keeping plans up to date [11][14].

Metals-Specific Compliance Features

EZIIL is built with the needs of the metals industry in mind, meeting EN 1090 EX2/3 standards for large, traceable metal contracts [11][12]. It offers full material traceability by linking EN 10204 3.1 material certificates directly to work records, creating a searchable certificate history. This ensures that every assembly is audit-ready without the tedious process of chasing down paperwork [13]. At Kane Metall, CEO Rainer Kütt leveraged EZIIL’s BOM software to set up a production drawing management platform and job order system in just one week, helping the company move closer to its €10 million sales goal [11][13].

Integration and Scalability

EZIIL operates on a modular subscription model, allowing businesses to pay only for the features they need, and subscriptions can be cancelled at any time [11][12]. It integrates seamlessly with tools like QuickBooks and supports Google and Microsoft Single Sign-On [11][12]. Most metal fabrication shops can start using EZIIL within a few days, with full team training and system go-live typically achieved by the third week [11][12]. The platform is designed to scale, accommodating small-to-medium-sized shops (5–50 people) as well as larger enterprises. Manufacturers are encouraged to begin with core scheduling features before expanding to modules like inventory tracking as their teams become familiar with the system [11][12][13]. This flexibility makes EZIIL a practical solution for modern metal production, streamlining both scheduling and operational workflows.

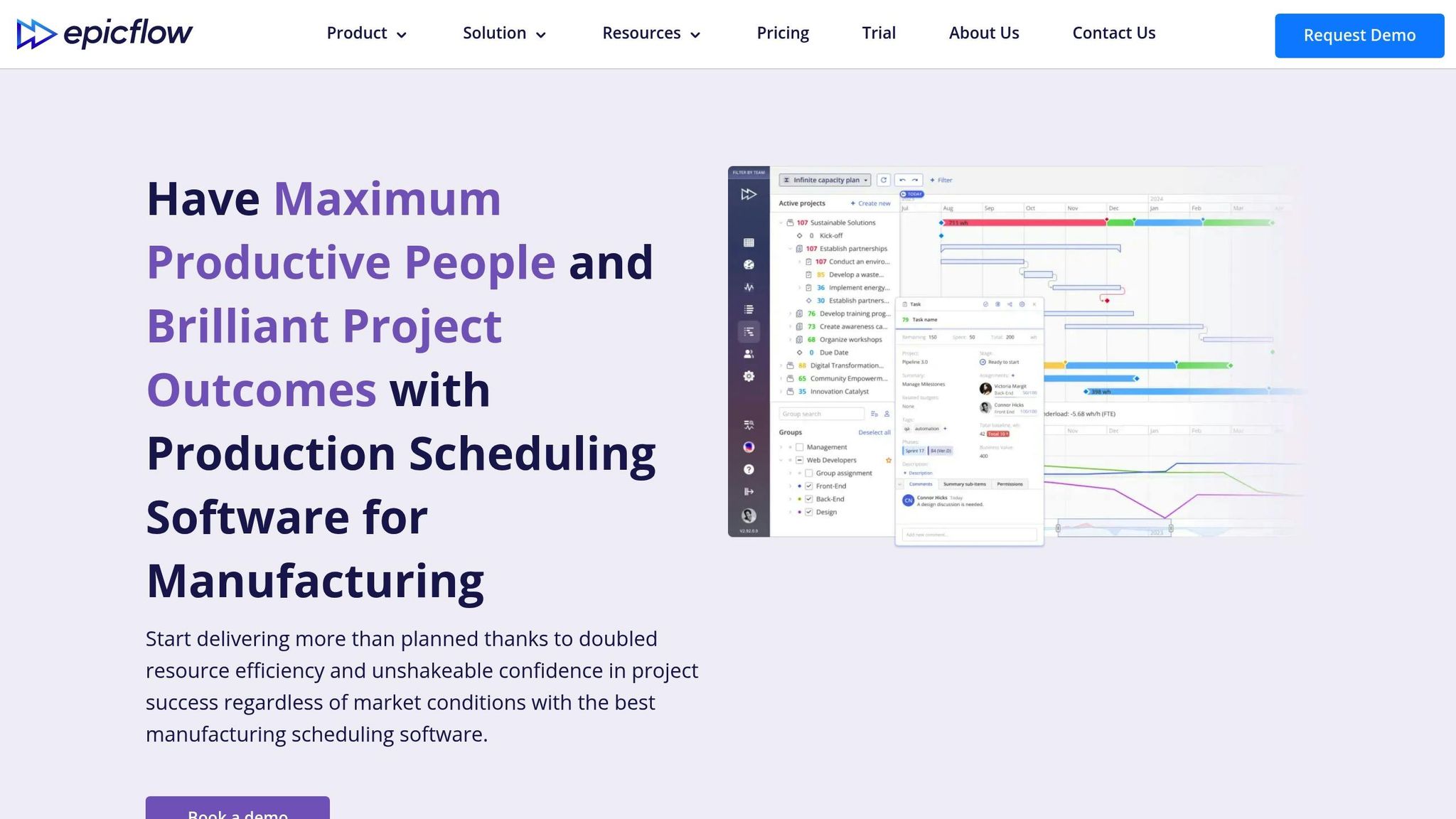

3. Epicflow

Epicflow

AI Automation Capabilities

Epicflow’s AI engine is designed to spot bottlenecks almost instantly and predict potential constraints before they can derail operations. It prioritises tasks and projects, creating a flexible plan that adjusts automatically as conditions evolve. With its scenario analysis tool, schedulers can safely explore “what-if” scenarios to test outcomes without any real-world risks. The platform also streamlines resource allocation by automatically assigning the most suitable personnel to tasks, based on their skills and availability. This ensures workloads are balanced, boosting productivity even in the intricate world of metal fabrication. Arnold AG shared their experience, stating:

Epicflow revealed opportunities to take extra projects in short notice which was not possible before [15].

Real-Time Scheduling and Optimisation

Epicflow takes automation further with real-time updates, ensuring production stays on track. It offers live insights into project progress, budget limits, and resource performance, empowering managers to make decisions based on the latest shop floor data. Unlike static legacy systems, Epicflow dynamically adjusts schedules as resources shift or priorities change. Employees benefit from AI-prioritised task lists that auto-update, keeping them focused on what matters most. This real-time adaptability enabled Arnold AG to significantly increase throughput without needing extra staff [15].

Integration and Scalability

Epicflow integrates effortlessly with existing enterprise systems, offering pre-built connections to platforms like SAP, Oracle Primavera, MS Project, and Jira. For unique needs, custom integration options are also available. To address concerns about data security, its DataGuard tool allows manufacturers to use cloud-based AI services while keeping sensitive data stored on-premises. This feature is particularly valuable in high-security industries like metals manufacturing. Additionally, the software meets the stringent penetration testing standards of both the British MOD and Dutch MOD, making it a reliable choice for mission-critical operations [15]. These features position Epicflow as a key tool in transforming traditional scheduling into a dynamic, AI-driven process.

4. Plataine Production Scheduler

Plataine

AI Automation Capabilities

Plataine’s AI scheduler relies on interconnected intelligent agents to streamline and coordinate manufacturing processes. At its core is the Practimum‑Optimum™ Algorithm, a proprietary AI engine designed to balance competing KPIs while considering on-the-ground constraints. Over time, it refines its performance to produce schedules that are both practical and efficient [26, 28]. The system can handle an impressive load, automatically managing and optimising more than 50,000 production tasks in real time, delivering detailed production plans in just minutes - tasks that would traditionally take days [27, 30].

A key feature of the platform is its ability to create a digital thread for every part, ensuring complete visibility and traceability from raw materials to finished products. This is particularly crucial for industries like aerospace and automotive [23, 26]. For processes such as heat treatment, the AI fine-tunes autoclave recipes, machine settings, and tooling options to enhance throughput while reducing energy use [19]. Manufacturers using Plataine have reported a 95% reduction in planning time compared to Excel-based methods and a 25% boost in On‑Time Delivery performance [24, 25]. This level of automation enables dynamic, real-time adjustments on the factory floor, keeping operations smooth and efficient.

Real‑Time Scheduling and Optimisation

Plataine excels at adapting to disruptions, whether it’s a machine breakdown, a sudden rush order, or a material shortage [24, 26]. Using IIoT sensors, the system provides immediate updates on equipment locations, raw material availability, and work-in-progress. When unexpected changes occur, manufacturers can use the “1‑click” algorithm feature to instantly reallocate resources, eliminating the hours typically needed for manual adjustments [17]. Thierry Ducro, Head of Procurement and Supply Chain at Airbus‑Hafei, praised the system:

Together with Plataine, we set the best possible processes in place, allowing us to gain full visibility and traceability over material and improve our overall efficiency [16].

The platform also supports goals-based planning, allowing manufacturers to define targets for specific objectives such as Overall Equipment Efficiency (OEE) or reduced make-span. This flexible approach has delivered up to 20% increases in factory output and 15% reductions in resource and expediting costs [23, 24].

Integration and Scalability

Plataine’s strength lies in its ability to integrate seamlessly with existing systems. It connects with ERP, PLM/CAD, and shop floor data while interfacing with enterprise platforms and IIoT devices [23, 27]. As a cloud-based SaaS solution, Plataine can be deployed in weeks rather than months and accessed from any browser, making it scalable without the need for extensive hardware investments [23, 25]. Its modular “Total Production Optimisation” suite allows manufacturers to start small, focusing on specific needs, and expand as their operations grow.

The platform is ISO 27001 certified and GDPR compliant, ensuring robust security for sensitive manufacturing data [25, 27]. It supports seamless data imports via CSV files or API connections. Avner Ben‑Bassat, President & CEO of Plataine, highlighted its transformative potential:

Plataine’s AI agents represent the future of manufacturing. By combining advanced automation with optimisation and seamless connectivity, we’re empowering manufacturers to unlock exceptional levels of cross‑functional productivity [18].

Manufacturers can explore the system with a 30-day trial, all without disrupting their current production processes [23, 25].

5. MachineMetrics

MachineMetrics

AI Automation Capabilities

MachineMetrics is driven by Max AI, an advanced intelligence layer that processes real-time data from machines, ERP systems, and internal SOPs to streamline production processes. Max AI takes charge of tasks like rescheduling work, identifying delays, initiating maintenance based on live machine data, and updating ERP cycle times to reflect what’s happening on the shop floor.

One standout feature is the Knowledge Hub, which transforms SOPs and machine manuals into actionable insights. It offers setup instructions and troubleshooting guidance exactly when needed, ensuring operations run smoothly while preserving critical institutional knowledge. Under Matt Townsend, the Director of Operational Excellence, one manufacturing facility managed to double its production capacity without adding new machinery. Furthermore, Continuous Improvement Managers Dave Roberts and Jordan Kathe achieved remarkable results: a 52% increase in asset utilisation and a 16.5% jump in productivity, respectively. Impressively, the platform also contributed to a 43% boost in overall equipment effectiveness (OEE) [20][21]. These automation capabilities enable dynamic, real-time schedule adjustments that keep operations efficient.

Real-Time Scheduling and Optimisation

MachineMetrics goes beyond automation by bridging the gap between planning and execution with real-time scheduling insights. It identifies jobs at risk of delays, monitors schedule health across the shop floor, and uncovers hidden resource capacity. With these tools, schedulers can track on-time delivery statuses and predict completion times, making informed adjustments on the fly. When disruptions occur - like machine downtime or alarms - automated workflows immediately notify maintenance teams or reorganise tasks.

For example, Carolina Precision Manufacturing saved over £1.2 million in one year by eliminating inefficiencies through machine monitoring. Meanwhile, Harvey Performance Company used MachineMetrics’ Intelligent MES to strengthen supply chain performance. Across the board, users reported an average manufacturing efficiency improvement of over 20%, with machine uptime increasing by 27% [21][23].

Integration and Scalability

MachineMetrics excels in connecting diverse equipment, from CNC machines to older legacy assets and manual stations. It supports various protocols, including MTConnect, Fanuc, OPC-UA, Modbus, and Ethernet IP [24]. ERP connectors seamlessly synchronise work orders, schedules, and labour data with systems like Epicor and Infor, while REST and GraphQL APIs allow developers to create custom applications and reports. Additionally, MQTT compatibility ensures real-time machine data is integrated into a unified system, providing a consistent and reliable source of information across business operations.

Pindel Global Precision, a contract machining company in Wisconsin, adopted MachineMetrics to build a connected factory and implement AI-driven production improvements. The platform leverages an Edge infrastructure to handle digital and analogue inputs for complex equipment, paired with a secure, scalable cloud system. Jordan Kathe, Continuous Improvement Manager, highlighted:

Everything that we wanted to build was already available with MM at a lower cost scalable, packaged solution.

MachineMetrics also addresses the challenges of manual tasks, which still account for 72% of factory operations. By tracking these processes through its Manual Stations, the platform provides complete visibility into scheduling, ensuring no task is overlooked [20][22][23].

6. AMFG Production Suite

AMFG

AI Automation Capabilities

The AMFG Production Suite leverages its AI-powered Holistic Build Analysis tool to deliver capacity and fill rate estimates in seconds, a process that traditionally takes hours or even days. Felix Doerr, Head of Business Development at AMFG, highlighted this efficiency:

With Holistic Build Analysis, instead of waiting hours to see how full your build is, our customers can receive an accurate capacity estimation in only a matter of seconds. [26]

The platform also automates the identification of optimal production times for processes like CNC machining, cutting, bending, and assembly, ensuring machines remain productive. Its dynamic rescheduling feature quickly resolves quality assurance issues, keeping operations running smoothly. Additionally, users can create tailored “digital worker” automations and custom scripts to eliminate repetitive tasks on the shop floor [25]. These tools are designed to streamline workflows and adapt to real-time production challenges.

Real-Time Scheduling and Optimisation

AMFG takes automation further by integrating real-time data from machinery, personnel, and material availability into its scheduling processes. The platform connects directly with production machines, offering live status updates and automatically re-planning builds when needed. For added flexibility, its drag-and-drop interface allows schedulers to manually adjust plans while monitoring live production updates.

The suite’s costing engine considers over 50 variables - such as CAD file details, machine expenses, and material costs - to generate precise quotes. With its automated scheduling interface, users can initiate order completion in as few as three clicks. Matthew Forrester, Technical Manager at L’Oréal, shared his experience:

We wanted to have a scalable solution, with which it’d be possible to start small and then add modules as our technology evolved and matured. This is something we have found with AMFG. [25]

Metals-Specific Compliance Features

For metals manufacturing, compliance is critical, and AMFG meets this need with task-level traceability across all production jobs, materials, and machine statuses. It tracks changes to jobs, heat codes, and worker assignments, ensuring compliance with stringent industry standards. The platform holds certifications like ITAR, Cyber Essentials Plus, and ISO, and supports government cloud environments in the US, Europe, and the UK, making it ideal for defence-related manufacturing. It also manages key fabrication technologies, including CNC machining, injection moulding, and additive manufacturing [25].

Integration and Scalability

AMFG offers over 500 integrations, connecting seamlessly with tools like CAD, PLM, ERP, CRM, accounting software, and business intelligence platforms such as Microsoft PowerBI and Tableau. It supports multi-site operations, with implementations in more than 35 countries. Major industrial players like ArcelorMittal, Ricoh, and HP rely on the platform [27].

Rich Proctor, Managing Director at AME Group, remarked:

Strategically, I could see that growing AME-3D would be an easier task when we were building on a platform that offers clarity, control, and consistency. [25]

7. o9 Production Scheduling

AI Automation Capabilities

The o9 platform employs a multi-algorithm approach to address the wide range of scheduling challenges faced by metals manufacturers. Designed to adapt to various shop floor setups and constraints, it ensures operations remain efficient and effective [28].

One of the standout features of the platform is its ability to take over repetitive, time-consuming tasks, freeing up human planners to focus on strategic activities. Brady Coady, Associate Vice President of Allocations and Merchandise, highlighted this shift in priorities:

o9 is moving the team’s workload and energy away from executing mundane, tedious tasks… We’re moving them upstream into preseason planning, into developing strategy, and then the system executes automatically. [28]

For metals manufacturers, the benefits are tangible. For instance, Chris Fink reported a 50% reduction in scrap due to better forecast visibility and smarter inventory management [28].

The platform also enables what-if scenario planning, allowing schedulers to evaluate production decisions in real time and minimise costs. This is particularly valuable in metals manufacturing, where material expenses and waste can have a direct impact on profit margins [30][31]. By transitioning seamlessly into real-time scheduling, the system ensures that all decisions are informed by the latest shop floor data.

Real-Time Scheduling and Optimisation

The o9 system is designed for near real-time production scheduling, integrating with MES, LIMS, and IoT devices to create a digital supply chain twin. This digital twin ensures that demand and supply stay aligned across both internal and external operations [31].

In October 2022, voestalpine High Performance Metals Division - a global leader in tool steel - chose the o9 Digital Brain platform to overhaul its supply chain planning. Dr. Reinhard Nöbauer, Member of the Management Board, described the platform’s impact:

The o9 platform will enable our supply chain and resource planning teams more reliable decisions much earlier by using intelligent forecast and what-if scenario planning capabilities. [30]

By integrating detailed scheduling with broader supply chain processes, the platform eliminates data silos, improving decision-making speed and accuracy. Bill Grah, Director of S&OP, shared his perspective:

The o9 platform makes our decision-making much faster. It’s also giving us a better and deeper understanding of the analytics, the cost of decisions, and now when we make those decisions, there’s greater confidence in execution. [28]

Integration and Scalability

Beyond its operational features, the o9 platform is designed for scalability. Built on a cloud-native architecture, it leverages its patented Enterprise Knowledge Graph (EKG) to quickly model and aggregate data across complex hierarchies. The in-memory columnar database ensures rapid query performance, even during live decision-making or significant data updates [28].

The platform connects seamlessly with major enterprise systems like SAP, Oracle, Azure Synapse, Google BigQuery, and Amazon Redshift. This connectivity allows metals manufacturers to integrate real-time performance data into their scheduling processes [28].

o9 Solutions has consistently been recognised as a leader in the Gartner® Magic Quadrant™ for Supply Chain Planning Solutions, earning the title for three consecutive years as of 2025. It also boasts a 4.8/5 customer review rating as of July 2025. Notably, it is the only vendor to be named a “Customers’ Choice” in the 2025 Gartner® Peer Insights™ for Supply Chain Planning Solutions [28][29][30].

Leading metals manufacturers, including voestalpine and Novelis, rely on the platform to navigate supply chain complexities and enhance resilience against challenges like trade wars, geopolitical instability, and regulatory shifts [29][30]. This highlights the industry’s growing preference for AI-driven, agile production scheduling solutions.

8. Genius ERP Smart Scheduling

Genius ERP

AI Automation Capabilities

Genius ERP brings Genius Cortex to the table, an AI-powered assistant that streamlines scheduling, quoting, and document automation tasks. This tool simplifies workflows, handles alerts, and automates document processing seamlessly [36][37].

The platform employs DBR (Drum-Buffer-Rope) scheduling to pinpoint and prioritise the shop floor’s bottlenecks, ensuring optimal capacity utilisation [32]. According to Genius ERP:

Smart Scheduling… is the only DBR scheduling tool built for custom manufacturers. [32]

One standout feature is the “What If” simulations, which let manufacturers explore the effects of adding or moving jobs before making any scheduling adjustments. This tool is especially handy for managing urgent customer demands or dealing with delays caused by late material deliveries [32]. For metal fabricators, the system includes production lot grouping, which clusters similar material orders - like those sharing the same gauge or alloy - boosting efficiency and throughput [33].

The results speak for themselves. Marathon Equipment slashed lead times by 50% and set the stage for a 20% revenue boost after adopting Genius ERP’s scheduling and shop-floor management tools [36]. Similarly, Jennison Manufacturing cut late orders by 30% by using smart scheduling to better align capacity with demand [36]. These features provide the foundation for real-time, dynamic process management.

Real-Time Scheduling and Optimisation

Genius ERP takes automation further with real-time scheduling, offering live dashboards and QR-code scanning to track job progress, inventory, and machine usage with incredible precision [34][36]. This real-time visibility helps teams spot and address bottlenecks immediately, preventing delays from spiralling into larger issues.

The CAD2BOM integration bridges engineering and production by automatically generating Bills of Materials (BOM) from CAD drawings [35][36]. This eliminates the risk of manual data entry errors, particularly in metal fabrication. Timothy Copp, VP of Business Development, highlighted the transformative impact:

Genius has been, in some ways, life-changing for the company, and has helped bring us into the 21st century. [35]

For sheet metal operations, Genius ERP integrates with nesting software to align inventory levels and material availability. It automatically updates production tasks and tracks material usage, reducing waste [33]. These tools have been shown to improve shipping performance by up to 37% [33]. The combination of real-time monitoring and seamless integration makes it adaptable to a wide range of manufacturing environments.

Integration and Scalability

Genius ERP stands out by blending automation with real-time insights, redefining how production control is managed. It integrates with CRM, accounting, and MES systems, offering live shop floor monitoring [34][35][37]. With both cloud and on-premise deployment options, it caters to small-to-mid-sized manufacturers looking to scale their operations [36].

Machitech Automation leveraged Genius ERP to unify engineering, inventory, and production processes, eliminating the manual updates that had previously hindered growth [36]. Tim Salihu, Engineering Supervisor, praised the support provided during implementation:

The implementation team was quite knowledgeable, especially on the custom manufacturing side - where we had a lot of questions. [35]

Tailored specifically for industries like sheet metal fabrication, industrial machinery production, and pressure vessel manufacturing, Genius ERP also caters to regulated sectors such as aerospace and defence, focusing on precision, quality, and traceability [35].

9. Blue Yonder Production Planning

Blue Yonder

AI Automation Capabilities

Blue Yonder leverages advanced AI technology, employing autonomous agents to monitor supply chains, generate actionable alerts, and recommend quick solutions to potential disruptions [38][40].

The platform handles over 20 billion predictions daily using transparent machine learning models [38]. Its Factory Planner tool is designed to balance customer demand with material and capacity constraints, creating efficient and adaptable production plans - an especially critical feature for resource-heavy industries like metals manufacturing [38]. As Blue Yonder explains:

Blue Yonder’s AI eliminates complexity and transforms data into rapid and well-informed actions. [38]

Manufacturers can also utilise ML Studio to develop, test, and deploy custom machine learning models at scale, addressing specific production challenges. Additionally, the platform incorporates a Supply Chain Knowledge Graph, developed in partnership with RelationalAI. This graph adds a semantic layer to data within the Snowflake AI Data Cloud, enabling manufacturers to make better decisions and respond swiftly to supply chain fluctuations [38].

Real-Time Scheduling and Optimisation

Blue Yonder’s Cognitive Planning integrates demand and supply planning, addressing the inefficiencies and delays commonly caused by outdated legacy systems [40]. Production plans are validated using digital twins, which compare real-time factory data against current schedules [41].

After acquiring flexis in February 2024, Blue Yonder expanded its capabilities to better support industrial manufacturers with complex supplier networks and highly configurable products [41]. The platform’s pearl chain sequencing feature ensures a balanced workload, helping to prevent bottlenecks. These scheduling tools can boost production throughput by up to 20%, improve sequence stability to 100%, and cut rework by up to 50% [41].

Metals-Specific Compliance Features

Blue Yonder also supports the metals industry by addressing strict compliance requirements. While its tools are not exclusive to metals, they meet key industry needs. For example, the platform includes carbon accounting for Scopes 1, 2, and 3, enabling manufacturers to track product carbon footprints directly within its quality and planning modules. This helps businesses comply with increasingly strict environmental regulations [39][42]. It also manages complex business rules and regulatory standards to ensure that production schedules align with legal and organisational requirements [38][39].

As Blue Yonder highlights:

Compliance and sustainability can no longer be treated as separate priorities. [39]

The platform’s Control Tower capabilities provide visibility across the supply chain, helping manufacturers avoid material shortages that could lead to costly production delays. This is especially beneficial for metals manufacturers managing intricate, multi-tier supplier networks [39].

Integration and Scalability

Blue Yonder enhances its usability with a common API framework and out-of-the-box data egress, enabling seamless integration with existing ERP and MES systems [40]. Its extension framework allows manufacturers to customise and scale its capabilities across both hybrid and SaaS environments [40]. By synchronising forecasting, fulfilment, and labour through a unified data cloud, the platform supports bi-directional data sharing across all supply chain tiers [38][40].

Blue Yonder notes:

A common API set and out-of-box data egress enable quick integration with existing solutions. [40]

Recognised as a Leader 12 times in the Gartner Magic Quadrant for Supply Chain Planning Solutions and featured as a Leader in five Nucleus Research 2025 Value Matrix reports [38][40], Blue Yonder has invested over £800 million in AI and supply chain advancements [38].

Practical approaches to using AI in manufacturing and fabrication

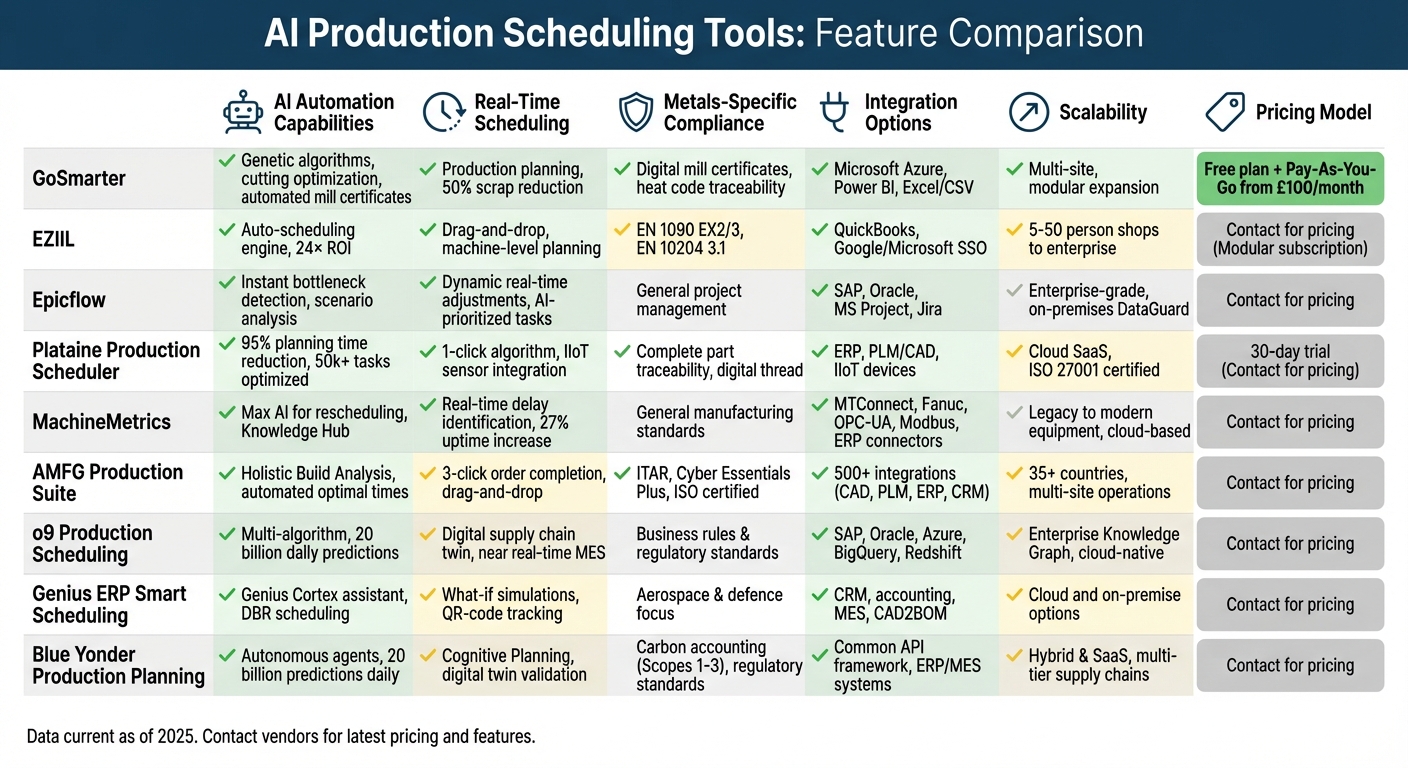

Feature Comparison Table

AI Production Scheduling Tools Comparison for Metals Manufacturing

Here’s a breakdown of how various tools perform in key areas like AI automation, scheduling, compliance, integrations, scalability, and pricing:

| Tool | AI Automation Capabilities | Real-Time Scheduling | Metals-Specific Compliance | Integration Options | Scalability | Pricing Model |

|---|---|---|---|---|---|---|

| GoSmarter | Genetic algorithms, cutting optimisation, automated mill certificates | Production planning, 50% scrap reduction | Digital mill certificates, heat code traceability | Microsoft Azure, Power BI, Excel/CSV | Multi-site, modular expansion | Free plan + Pay-As-You-Go from £100/month |

| EZIIL | Auto-scheduling engine, 24× ROI | Drag-and-drop, machine-level planning | EN 1090 EX2/3, EN 10204 3.1 | QuickBooks, Google/Microsoft SSO | 5–50 person shops to enterprise | Contact for pricing (Modular subscription) |

| Epicflow | Instant bottleneck detection, scenario analysis | Dynamic real-time adjustments, AI-prioritized tasks | General project management | SAP, Oracle, MS Project, Jira | Enterprise-grade, on-premises DataGuard | Contact for pricing |

| Plataine Production Scheduler | 95% planning time reduction, 50k+ tasks optimized | 1-click algorithm, IIoT sensor integration | Complete part traceability, digital thread | ERP, PLM/CAD, IIoT devices | Cloud SaaS, ISO 27001 certified | 30-day trial (Contact for pricing) |

| MachineMetrics | Max AI for rescheduling, Knowledge Hub | Real-time delay identification, 27% uptime increase | General manufacturing standards | MTConnect, Fanuc, OPC-UA, Modbus, ERP connectors | Legacy to modern equipment, cloud-based | Contact for pricing |

| AMFG Production Suite | Holistic Build Analysis, automated optimal times | 3-click order completion, drag-and-drop | ITAR, Cyber Essentials Plus, ISO certified | 500+ integrations (CAD, PLM, ERP, CRM) | 35+ countries, multi-site operations | Contact for pricing |

| o9 Production Scheduling | Multi-algorithm, 20 billion daily predictions | Digital supply chain twin, near real-time MES | Business rules & regulatory standards | SAP, Oracle, Azure, BigQuery, Redshift | Enterprise Knowledge Graph, cloud-native | Contact for pricing |

| Genius ERP Smart Scheduling | Genius Cortex assistant, DBR scheduling | What-if simulations, QR-code tracking | Aerospace & defence focus | CRM, accounting, MES, CAD2BOM | Cloud and on-premise options | Contact for pricing |

| Blue Yonder Production Planning | Autonomous agents, 20 billion predictions daily | Cognitive Planning, digital twin validation | Carbon accounting (Scopes 1‑3), regulatory standards | Common API framework, ERP/MES systems | Hybrid & SaaS, multi‑tier supply chains | Contact for pricing |

This table underscores how each solution tackles the specific hurdles faced by British metals manufacturers, aiming to streamline operations and reduce reliance on paper-based systems.

For manufacturers in the UK looking for immediate gains, GoSmarter stands out with its affordable entry point and measurable results. With as little as £275 monthly investment, businesses can break even each month from freed-up staff time alone [10]. The platform also cuts scrap rates by 50% and automates mill certificate management, saving up to 120 hours per year [2].

Meanwhile, tools like o9 Production Scheduling and Blue Yonder Production Planning cater to larger-scale enterprises, offering robust capabilities for multi-site operations. However, their pricing is typically customised, reflecting the tailored nature of their deployments.

For those exploring new solutions, prioritising platforms with free trials or modular setups can help evaluate their impact before committing to a full-scale rollout.

How Metals Manufacturers Benefit

AI-powered production scheduling brings measurable improvements to metals manufacturers, particularly in four key areas: efficiency, cost savings, compliance management, and decision-making quality. Many companies in the sector have reported notable progress within just months of implementing these technologies. Here’s a closer look at how these advancements are transforming the industry.

AI dramatically boosts efficiency by simplifying and accelerating production scheduling. For instance, it can cut the time needed to create schedules by up to 90% [1]. This shift frees planners from hours of manual coordination, allowing them to focus on higher-value tasks. A compelling example comes from Spartan UK’s Gateshead mill, where AI analysed 40 years of data to alert operators when steel hit its target temperature. This adjustment increased productivity by 20% and reduced energy usage by 24 kWh per tonne [5]. Osas Omoigiade, Founder of Deep.Meta, highlighted the impact:

One operator, who has been there for 30 years, told me that this tool made his job five times faster, reducing the risk of operator errors. [5]

When it comes to cost savings, the results are equally striking. Midland Steel managed to halve its scrap rates through AI-driven production planning during a pilot project with the GoSmarter platform [2]. Across the industry, AI solutions are estimated to save between £17 and £44 per metric tonne of steel produced [3]. Additionally, optimised scheduling can trim scheduling costs by 5–15% [1]. Predictive maintenance is another area where AI shines, as it identifies equipment issues before they cause costly downtime. For example, one plant increased cold mill productivity by 1% through AI-driven root cause analysis, resulting in approximately £780,000 in financial benefits [43].

AI also reshapes compliance management by automating time-consuming tasks. For example, AI tools can digitise mill certificates, converting large volumes of documents into searchable records linked to specific heat codes, saving production managers over 120 hours annually [2]. These systems also enhance quality assurance by using computer vision to detect defects and verify material integrity for critical processes like welding. The result? A more streamlined, reliable approach to meeting rigorous quality standards.

Finally, AI significantly improves decision-making quality by providing real-time insights into constraints such as capacity, materials, labour, energy costs, and deadlines. Digital twin technology allows manufacturers to simulate “what-if” scenarios without disrupting actual production, while explainable AI features generate detailed evidence packages that clarify the reasoning behind scheduling decisions. This transparency not only supports audits but also fosters continuous improvement efforts.

How to Select the Right Tool

Picking the right AI scheduling tool begins with a clear understanding of your production needs. If your processes involve specifics like heat codes, alloy recipes, or cutting plans for long products such as rebar, you’ll need a solution tailored for metals manufacturing [6]. General-purpose tools often fall short when it comes to handling details like scrap mix optimisation or minimising ferroalloy recipes.

Integration is key. The tool you choose should seamlessly connect with your existing ERP, MES, and plant control systems. This ensures all your data is unified in one place, breaking down silos and creating a reliable source of information [28]. For smaller operations, it’s important to find a solution that fits smoothly into your current workflows without unnecessary complexity.

Another critical factor is the tool’s data requirements. Some platforms might need months of manual data labelling, while others use unsupervised learning to identify patterns from existing sensor data [43]. As Ryan Goltz, Chief Architect at a manufacturing firm, highlighted:

Falkonry removes a number of very serious hurdles - I am not aware of any other solution that simplifies the data ingest, data visualisation, model development, model deployment, and operations like Falkonry [43].

Modern AI tools are designed to deliver results quickly, with many implementations going live and showing value within 90 days [44]. This makes it essential to prioritise solutions that offer rapid deployment and dependable performance.

Budget considerations also play a big role. To manage costs effectively, start small - perhaps with a single module like scrap optimisation or energy management - and expand as needed [44]. This modular approach keeps expenses under control while meeting your specific production needs. Many providers even offer free trials or tools to benchmark performance before committing to full deployment [2].

Beyond cost and data, the ability to run “what-if” scenarios is invaluable. This feature allows you to model the effects of changes in labour, inventory, or machine downtime before making real-world adjustments [44]. Bill Grah, Director of S&OP at a manufacturing firm, explained:

The o9 platform makes our decision-making much faster. It’s also giving us a better and deeper understanding of the analytics, the cost of decisions, and now when we make those decisions, there’s a much higher degree of confidence that we actually execute [28].

Finally, look for tools with user-friendly, no-code interfaces. These make it easier for engineering teams to manage and adjust models without needing advanced data science skills.

Conclusion

AI is transforming metals manufacturing by replacing outdated, manual scheduling methods with fast, data-driven solutions. These AI-powered tools can reduce scheduling time by as much as 90%, all while improving the use of capacity, materials, and labour resources [1]. This evolution allows production managers to shift their focus from tedious administrative tasks to more strategic decision-making.

The benefits go beyond time savings. AI adoption can lead to substantial cost reductions - ranging from £18 to £47 per metric tonne of steel [3]. Additionally, specialised tools help cut material waste [2], improve delivery performance by 5–15% in On-Time In-Full metrics [1], and contribute to lower energy consumption and carbon emissions, supporting sustainability goals.

The AI tools highlighted here each bring distinct advantages. For instance, GoSmarter’s mill certificate automation saves more than 120 hours annually [2], while other platforms offer advanced features like scenario planning and digital twin technology. As Ansgar Jüchter from ArcelorMittal Hamburg pointed out:

AI that actually gives tangible value. It decreases the cost of tapped liquid metal, whilst maximising quality, and productivity [4].

FAQs

How can AI tools speed up production scheduling in metals manufacturing?

AI tools have transformed production scheduling by automating data analysis and creating schedules that account for constraints and optimise efficiency. They take key inputs like demand forecasts, inventory levels, and available resources, then use advanced algorithms to generate production plans almost instantly.

This automation removes the need for manual scheduling, saving valuable time and reducing the risk of errors. It also allows manufacturers to adapt quickly to shifts in demand or resource availability, leading to smoother operations and better overall efficiency.

How does AI help reduce costs in production scheduling for metals manufacturers?

AI-driven production scheduling can help businesses save money in several ways. By cutting down on downtime, reducing material waste, and using energy more efficiently, it ensures resources are managed wisely. It also helps plan maintenance better, avoiding unexpected delays that could disrupt operations.

With smoother workflows and improved output, metals manufacturers can boost productivity while trimming unnecessary costs. This approach not only makes operations run more smoothly but also supports a more economical and resource-conscious production process.

How can AI tools help metals manufacturers stay compliant?

AI tools are proving invaluable for metals manufacturers, helping them stay compliant by automating key processes, minimising manual errors, and ensuring traceability. Take GoSmarter’s MillCert Reader, for example. This tool scans and extracts critical details from mill certificates, such as chemical composition and mechanical properties, while organising the data with standardised naming conventions. The result? No more tedious manual data entry, and all certificates are neatly stored and easily accessible for quality compliance checks.

On top of that, AI-driven scheduling systems embed compliance rules directly into their optimisation processes. These systems factor in material grades, heat-treatment restrictions, safety standards, and even environmental regulations, adapting schedules dynamically as new information comes in. Transparent reporting features further simplify the process by documenting decisions clearly, making it straightforward to demonstrate compliance during audits.

With automated document management, rule-based scheduling, and real-time monitoring working together, AI tools help metals producers across the UK meet regulatory requirements efficiently - without disrupting production workflows.