AI‑Powered Flow Optimisation: What Leading Metals Producers Know That You Don't

- Steph Locke

- Blog

- January 8, 2026

Table of Contents

AI‑Powered Flow Optimisation: What Leading Metals Producers Know That You Don’t

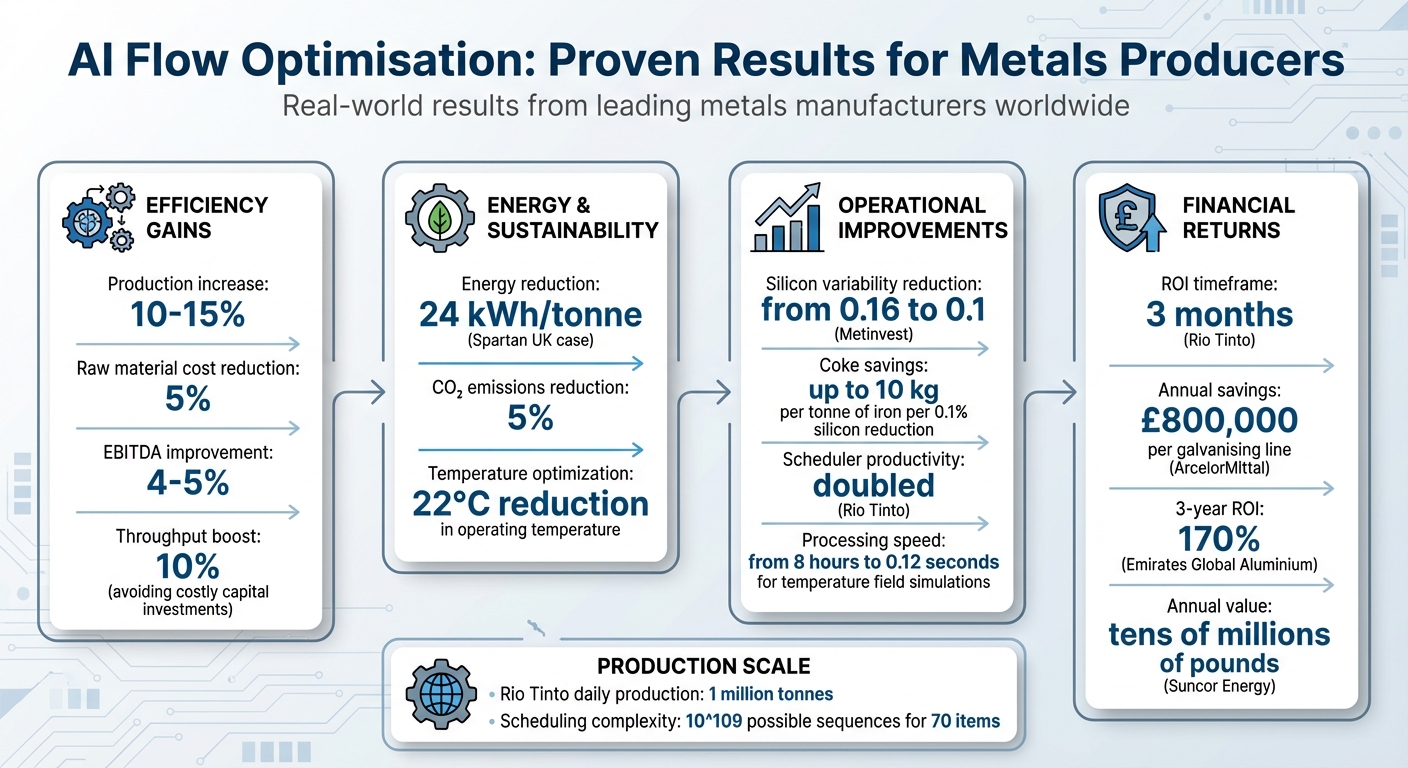

AI-driven flow optimisation is transforming metals manufacturing by improving efficiency, reducing costs, and supporting sustainability goals. It enables producers to optimise production processes, from blast furnaces to finishing lines, by analysing vast amounts of data and uncovering patterns that human operators might miss. Here’s what you need to know:

- Efficiency Gains: AI can boost production by 10–15%, cut raw material costs by 5%, and improve EBITDA by 4–5%.

- Energy Savings: UK producers like Spartan UK have reduced energy use by 24 kWh/tonne and CO₂ emissions by 5%.

- Real-Time Decisions: AI adjusts processes in the moment, such as tweaking furnace temperatures or rerouting materials, to maintain quality and throughput.

- Data-Driven Insights: Systems like Rio Tinto’s optimise complex supply chains, achieving ROI in just three months.

Starting with AI involves identifying bottlenecks, preparing reliable data, and integrating AI as a decision-support tool for operators. Early successes, like those seen with Freeport-McMoRan and ArcelorMittal, show the financial and operational benefits of embracing AI in metals production. For UK manufacturers, this approach offers a clear path to increased efficiency and reduced environmental impact.

AI Flow Optimisation Benefits for Metals Producers: Key Performance Metrics

How AI Flow Optimisation Works

Machine Learning and Optimisation Basics

AI systems learn by analysing historical production data, moving beyond static, rule-based approaches. Machine learning models dig into years of production records - covering details like temperatures, flow rates, chemical compositions, and equipment states - to identify patterns and relationships that might escape even the sharpest human operators. These patterns often involve thousands of interacting variables, making them incredibly complex.

For instance, ArcelorMittal employs a system based on “Ant Colony Optimisation” (ACO), a bio-inspired algorithm that mimics the way ants find the shortest paths to food. In one of their galvanising lines with 70 items, the possible sequencing combinations exceed 10^109 - a number far greater than the total atoms in the observable universe (about 10^80). Traditional computers would need years to process all options, but ArcelorMittal’s ACO algorithm delivers an optimal schedule in just minutes[4].

“The artificial intelligence we have created using bio-inspired algorithms allows us to achieve superior performance without purchasing high-cost solutions from vendors.” – Carlos Alba, Chief Digital Officer at ArcelorMittal Global R&D[4]

AI thrives by uncovering hidden rules through methods like supervised learning (using labelled data) and unsupervised learning (finding patterns without predefined labels). This adaptability means AI systems can evolve with changing conditions, avoiding the pitfalls of static assumptions that quickly become outdated. The insights drawn from these patterns influence both long-term strategies and immediate operational decisions.

Real-Time vs Planning Decisions

AI operates on two main levels, each serving a distinct purpose. At the strategic level, planning-based optimisation focuses on long-term goals like scheduling production runs, balancing energy demand with supply, and allocating resources over hours, days, or even weeks. It tackles questions like: “What production schedule will maximise efficiency given tomorrow’s energy prices?”

On the other hand, real-time optimisation works in the moment, making adjustments every second or minute. Using live sensor data, it can tweak processes like adjusting furnace oxygen levels, rerouting materials, or altering temperatures based on changing ore compositions.

A compelling example is Suncor Energy’s AI “lead advisor”, launched in January 2019. This system combines strategic planning with real-time adjustments, learning continuously from sensor data without needing a pre-built plant model. It provides near real-time advice to optimise throughput, delivering an estimated tens of millions of pounds in annual value[10]. Think of it like a GPS for production: while planning sets the route, real-time optimisation recalculates instantly when unexpected issues - like equipment breakdowns - arise.

| Feature | Planning-Based Optimisation | Real-Time Optimisation |

|---|---|---|

| Primary Goal | Strategic scheduling & resource alignment | Tactical set-point & process adjustment |

| Time Horizon | Hours, days, or weeks | Seconds, minutes, or near real-time |

| Data Source | Production orders, energy forecasts | Live sensor data, SCADA, IoT |

| Example Action | Scheduling a specific “heat” for 14:00 | Adjusting furnace oxygen levels mid-melt |

By combining these two approaches, AI-driven flow optimisation becomes a powerful tool for improving efficiency and decision-making.

Data and Constraints: What AI Needs to Work

For these optimisation strategies to succeed, AI systems depend on high-quality data and clearly defined constraints. Reliable sensor data - covering flow rates, temperatures, and equipment states from SCADA systems - is a must. AI also needs detailed material and chemical data, such as raw material availability, composition certificates, and real-time thermal analyses.

“The optimal load to be proposed by the system consists of the one that meets two criteria simultaneously: offering sufficient metallurgical quality to manufacture without defects and doing so at the lowest cost possible.” – Dr. Javier Nieves, Head of Intelligent Manufacturing Technologies at AZTERLAN[7]

Constraints play an equally important role. AI systems must respect physical laws, like mass conservation and temperature limits (e.g., avoiding slag freezing). They also need to account for operational factors such as equipment schedules, process routes, and material delays. External variables like fluctuating energy costs, raw material prices, and CO₂ emission caps further shape the boundaries within which optimisation occurs.

A standout example is Rio Tinto’s AI-driven platform, which supports the world’s largest integrated iron ore supply chain, producing 1 million tonnes per day. This system uses machine learning and optimisation algorithms to assist 50 schedulers in making real-time decisions for rail and port operations across Western Australia. The results were impressive: increased production, doubled scheduler productivity, and a full return on investment in under three months[9]. This success highlights the power of combining comprehensive data with well-defined constraints to turn overwhelming complexity into actionable insights.

Real-World Use Cases of AI in Metals Flow Optimisation

Blast Furnace and Ironmaking Flow Optimisation

Managing blast furnaces is no small feat. With a mix of variables like temperature, chemical composition, fuel rates, and ore characteristics, traditional control systems often fall short. This is where AI steps in, offering the ability to predict critical factors such as silicon content in cast iron - a key indicator of a furnace’s thermal state.

Take Metinvest, a steel producer based in Ukraine, as an example. In August 2021, they launched an AI pilot using Azure Machine Learning to predict silicon content over a 9-hour timeframe. The results? Silicon variability dropped from 0.16 to 0.1, giving operators the stability they needed to fine-tune thermal conditions. Why does this matter? A 0.1% reduction in silicon content can save up to 10 kilogrammes of coke per tonne of iron. Operators accessed these insights through a Power BI dashboard updated hourly [11].

“Reducing the silicon content by 0.1 per cent can allow us to save up to ten kilogrammes of coke. Thus, we need to stabilise the blast furnace process and reduce the variability of the silicon content in cast iron.” – Kirill Makarov, Director of Continuous Improvement, Metinvest Holding [11]

AI’s benefits go beyond prediction. It digs into the root causes of inefficiencies in smelting processes. For instance, one industrial site used machine learning to analyse temperature buffers, achieving a 22°C reduction in average operating temperature while improving recovery rates [5]. These advancements highlight how AI is reshaping metals manufacturing for better efficiency and performance.

Continuous Casting and Mill Operations

Continuous casting, like blast furnace operations, thrives on precision and speed - areas where AI excels. Casting lines require split-second decisions to balance product quality with production speed. Traditional numerical simulations of 3D temperature fields often take up to 8 hours, far too slow for real-time adjustments. AI-powered models, however, can crunch the same data in just 0.12 seconds, enabling dynamic control over casting speed and cooling water flow [12].

ArcelorMittal turned to bio-inspired algorithms for production scheduling on its hot dip galvanising lines. The complexity here is staggering - a single day’s production of 70 items involves over 10^109 possible sequences, a figure that dwarfs the number of atoms in the observable universe. Using an Ant Colony Optimisation (ACO) algorithm, ArcelorMittal generated optimal schedules in minutes, saving nearly £800,000 annually per galvanising line. Extending this approach to steel shops has multiplied these savings three- to four-fold [4].

AI also plays a critical role in maintaining material quality, especially when using recycled scrap. By monitoring trace elements like titanium, aluminium, and zinc, AI suggests the best raw material recipes to meet chemical composition targets at the lowest cost [7].

“The optimal load to be proposed by the system consists of the one that meets two criteria simultaneously: offering sufficient metallurgical quality to manufacture without defects and doing so at the lowest cost possible.” – Dr Javier Nieves, Head of Intelligent Manufacturing Technologies, AZTERLAN [7]

The results speak for themselves: operators report production increases of 10–15% and EBITDA gains of 4–5% [5].

Logistics and Finishing Process Improvements

AI doesn’t stop at production - it also transforms logistics and finishing processes, turning complex coordination tasks into streamlined operations. Managing the movement of slabs, coils, carriers, and ladles across multiple production stages is a logistical nightmare that AI simplifies through proactive orchestration.

Energy-integrated scheduling is another game-changer, aligning production needs with energy availability to reduce peak energy usage - a critical step toward decarbonisation [3].

Sandvik Materials Technology tackled logistics and recycling challenges through its “Swedish Metal” project, launched in 2018 in partnership with SSAB and the University of Skövde. AI was used to analyse the composition of internally recycled materials. While Sandvik already uses recycled steel and residual products for about 45% of its melt, it still relies on 20% pure metal alloys. By employing machine learning to pinpoint metal losses and contaminants, the company aims to increase recycled material usage without compromising quality [13].

“We expect to be able to find better ways of utilising the recycled material so that it is possible to reduce the proportion of alloys without risking poorer quality in the final product.” – Magnus Josefsson, Responsible for Raw Material Optimisation, Sandvik [13]

From scheduling trains to sequencing coils and optimising scrap usage, AI processes thousands of variables at once - delivering solutions that would take human planners weeks to calculate.

What You Need for AI Flow Optimisation

Data Preparation and Integration

For AI flow optimisation to work effectively, you need reliable, structured, and real-time data. AI models thrive on process measurements like temperature, gas flow, feed rates, and pressures, as well as material chemistry data such as ore assays, alloy percentages, and tap weights. Equipment health metrics, including vibration, current, and hydraulics telemetry, are also critical for predicting potential issues before they disrupt operations [14][15].

Integrating this data is usually straightforward with existing systems like data historians, SCADA systems, and control systems. However, the real challenge lies in cleaning the data - mapping sensors, identifying faulty tags, and ensuring continuous validation of model performance. Centralising this data in a cloud-based lake or digital twin can streamline access across the organisation and simplify model training [5].

Tools like GoSmarter can help by automating the integration of data from mill certificates, inventory systems, and production records. This turns fragmented data into actionable insights. Once your data is clean and integrated, the next step is embedding AI into everyday operations.

Integrating AI into Daily Operations

Rather than handing over full control to AI, it’s often better to deploy it as a “control room adviser.” In this role, AI provides recommendations that human operators can review and approve, which helps build trust and confidence in the system. Agile workflows, such as two-week sprints and daily stand-ups, are effective for refining AI models and addressing any issues operators face during shifts [1][8].

A great example of this approach is Spartan UK, a steel re-roller in Gateshead. By 2025, they had implemented the Deep.Optimiser AI platform, which uses live furnace sensor data and four decades of historical production data to predict the exact moment steel is ready for rolling. Osas Omoigiade, the founder, highlighted how the tool enhanced operator efficiency; one operator with 30 years of experience said it made his work five times faster while significantly reducing errors [6].

To make this process work, it’s essential to form multidisciplinary teams that include data scientists, metallurgists, process engineers, and operators. These teams can address practical challenges and ensure AI recommendations are both useful and realistic [8].

Clear communication is also key. Interfaces or Generative AI tools should explain the reasoning behind AI recommendations to avoid the “black box” effect, which can breed scepticism. Interestingly, some operators even begin predicting AI suggestions, effectively competing with the system and improving their own performance. This kind of engagement shows that the AI is being well-received and integrated into daily workflows [5][8].

Tracking and Measuring Results

Once AI is up and running, it’s crucial to track its impact on production and efficiency. Start by establishing a baseline using historical data on key metrics like throughput (tonnes per hour), recovery rates, energy consumption (kWh per tonne), and scrap rates. These benchmarks will help you measure the improvements driven by AI [8].

Operator acceptance rates are another important metric. A high acceptance rate - above 80% - indicates that the AI is delivering recommendations that supervisors trust and act on [8]. Financial metrics like EBITDA uplift and profit per hour should also be monitored, alongside operational metrics such as reduced process variability and better equipment utilisation.

Sustainability metrics are equally important. Keep an eye on CO₂ emissions per tonne and energy savings to align with ESG goals. For UK metals producers, these efficiency gains often translate into measurable operational savings [2][3][6].

To maximise results, focus on bottlenecks where AI can deliver throughput increases of 10–15% [1][5]. This targeted approach ensures you’re addressing the areas with the most room for improvement.

How to Start with AI Flow Optimisation

Choosing the Right Pilot Areas

When starting with AI in manufacturing, it’s smart to focus on bottlenecks - those tricky areas where complex interactions slow things down. Think of grinding mills, blast furnaces, continuous casters, or reheating stages. These are spots where countless variables interact in unpredictable ways, and even small tweaks can lead to noticeable improvements in throughput [1][6].

Here’s the kicker: tackling these bottlenecks can lead to a 10% boost in throughput, potentially saving you from costly capital investments [8].

For UK metals producers, processes tied to strict compliance standards are great pilot options. Areas already tracking energy usage, emissions, or material chemistry provide ready-to-use data streams and clear regulatory benchmarks. The sweet spot? Choose a process where a 10–15% improvement would make an immediate and meaningful financial impact [1][5].

Once you’ve pinpointed the right area, the next step is to follow a structured plan for implementation.

Step-by-Step Implementation Plan

- Start with a data audit. Map out your sensors, identify faulty tags, and create a centralised, real-time data warehouse. This step is critical - poor data leads to unreliable AI outputs, which can harm both equipment and trust [2][8].

- Train the AI using historical data. For example, Freeport-McMoRan used two-week agile sprints to develop and refine their AI, constantly testing ideas and learning from operator feedback. Spartan UK in Gateshead took a similar approach, training their “Deep.Optimiser” tool with 40 years of production data to predict optimal furnace temperatures [6][8].

- Test in shadow mode. Run the AI alongside existing systems for several weeks. This allows experts to evaluate its suggestions and catch any potential errors before full integration.

“Agile can be tricky to adopt at first because it isn’t a process you can memorise. It’s a set of principles for minimising wasted effort.” – Shannon Lijek, Partner at McKinsey [8]

- Integrate gradually. Once the AI has proven itself, incorporate it into your Distributed Control Systems (DCS). Position it as a control room adviser rather than an autonomous operator, keeping human experts in the loop and allowing them to override recommendations when needed [5][8].

Compliance and Risk Management

After your AI system is up and running, the focus shifts to compliance and risk management to ensure smooth and secure operations.

- Prioritise data security and traceability. Make sure your AI aligns with industry standards like AMIRA P754 for metallurgical accounting, ensuring data accuracy and auditability [2]. UK producers should also consider how AI can support initiatives like the Sustainable Smart Factory programme and help meet net-zero goals.

One standout example is Spartan UK’s project, which wrapped up in February 2024. Their AI system reduced energy consumption by 24 kWh per tonne of steel and cut CO₂ emissions by 5% during reheating and finishing processes. Chris Needham, Innovation Lead at Made Smarter Innovation, highlighted its importance:

“Developing new digital innovations to improve the sustainability of manufacturing processes is vital for industry to achieve a net zero future.” – Chris Needham, Innovation Lead at Made Smarter Innovation [6]

- Build multidisciplinary teams. Include data scientists, metallurgists, process engineers, and IT specialists. This ensures AI recommendations are not only technically accurate but also transparent and practical [1][5][8].

- Regularly update the AI model. As equipment ages and processes evolve, it’s crucial to validate the AI’s recommendations against current production data. This keeps the system reliable and maintains operator confidence [8].

How AI Is Increasing Production Quality in Steel Manufacturing

::: @iframe https://www.youtube.com/embed/dPCtdHGKQIw :::

Conclusion: Making AI Flow Optimisation Work for Your Business

AI flow optimisation isn’t reserved for global mining giants - it’s a practical solution that UK metals producers can use to increase throughput, reduce costs, and work towards net-zero goals. Industrial operators using AI in processing plants have reported 10% to 15% production increases and 4% to 5% EBITDA improvements [1][5]. For UK manufacturers grappling with slim margins and rising energy costs, these kinds of gains can be game-changing. The best way to unlock this potential? Start small and focused with pilot initiatives.

The process is straightforward. Target a known bottleneck - like a blast furnace, continuous caster, or reheating stage - where even small improvements can deliver clear financial benefits. Test the AI in shadow mode to validate its accuracy, then integrate it step by step, ensuring human expertise remains central. This method has already delivered results for producers such as Spartan UK in Gateshead, which achieved a 24 kWh per tonne reduction in energy consumption and a 5% decrease in CO₂ emissions [6]. These early wins lay the groundwork for more agile and efficient operations.

GoSmarter simplifies this journey by automating data pipelines and integrating seamlessly with your existing systems. It allows you to shift from reactive problem-solving to proactive, data-driven decision-making. With a free plan to get started and pay-as-you-go pricing that adjusts to your needs, it’s tailored to the realities of UK metals manufacturing.

Start with a small-scale pilot, track the outcomes, and then expand on proven successes. Key metrics like recommendation acceptance rates, throughput improvements, and profit per hour can help you measure the AI’s impact. As Emirates Global Aluminium demonstrated with its 170% ROI over three years [16], AI flow optimisation often pays for itself - early successes can fund future IT investments and drive broader adoption across your organisation.

“Speed, agility, efficiency, and technology mastery are now core attributes for the future.” – Carlo Nizam, Chief Digital Officer, Emirates Global Aluminium [16]

In the next decade, the metals producers that succeed won’t necessarily be the ones with the deepest pockets. Instead, they’ll be the ones leveraging AI to make smarter, faster decisions every day. The strategies outlined in this guide align with the growing need for efficiency and data-driven decision-making, which are now essential for staying competitive in modern metals manufacturing.

FAQs

::: faq

How can AI enhance efficiency in metals production?

AI is transforming metals production by processing massive amounts of data - like sensor outputs, ore compositions, and equipment performance metrics - to enable real-time, informed decision-making. Through machine learning, it uncovers intricate connections between factors such as furnace temperatures, energy consumption, and material properties. This allows for precise adjustments that fine-tune production processes.

Take, for instance, how AI can forecast the best settings for individual production units. Operators can then tweak feed rates, optimise scrap mixtures, or refine cooling schedules to boost output while upholding quality and safety. The use of digital twins enhances this further by allowing manufacturers to simulate and test various scenarios, ensuring smoother workflows and minimising waste. These advancements not only increase efficiency and cut costs but also support more sustainable practices, delivering immense benefits to metals producers across the UK and beyond. :::

::: faq

How can metals producers get started with AI-powered flow optimisation?

Getting started with AI-powered flow optimisation in a metals production facility requires a clear plan. First, define your goals. Ask yourself what you want to achieve - whether it’s boosting production rates, cutting down on energy expenses, or improving product quality. Make sure these goals align with both your operational needs and financial targets.

Once your objectives are in place, bring together a multidisciplinary team. This should include data scientists, process engineers, IT experts, and metallurgists. Each team member will play a role in handling data, building models, and ensuring the AI solution integrates smoothly into your organisation.

Next, focus on your data. Collect and organise information from various sources like sensor readings, control system logs, and lab analysis reports. Clean and consolidate this data to create a reliable foundation for training your AI models.

To test and refine your approach, create a simulation or digital twin of your plant’s operations. This virtual environment allows you to safely train optimisation algorithms without disrupting actual production. Start small with a pilot project in one specific area. Compare the results against your baseline KPIs to ensure the AI is delivering measurable improvements.

Finally, once the pilot proves successful, gradually expand the solution across the facility. Embed it into your daily workflows and keep an eye on performance. Regular monitoring and retraining of your AI models will help maintain and improve results over time. :::

::: faq

How does AI make real-time decisions in manufacturing processes?

AI plays a crucial role in enabling real-time decision-making in manufacturing by analysing live data from factory floor sensors. By leveraging predictive models, it assesses current operational conditions and uses optimisation algorithms to recommend immediate actions. These might include tweaking production schedules or fine-tuning process settings. What’s impressive is how these systems can adjust on the fly to changes, such as equipment downtime or material inconsistencies, keeping operations efficient and productive.

In the metals industry, for instance, AI tools tackle intricate challenges like managing furnace availability, maintaining precise chemical compositions, and meeting sustainability goals. By automating adjustments and delivering actionable insights, these technologies help manufacturers boost output, cut costs, and improve overall performance. Many businesses have reported millions of pounds in annual savings after integrating AI-powered solutions into their operations. :::