AI in ERP: Smarter Production Scheduling

- Steph Locke

- Blog

- January 9, 2026

Table of Contents

AI-powered ERP systems are transforming production scheduling in manufacturing, especially in metals. They replace outdated manual processes with real-time, data-driven solutions, addressing common issues like bottlenecks, downtime, and material delays. Key benefits include faster planning, better resource use, and improved delivery rates. For example, Lenovo cut planning times from two hours to two minutes and boosted capacity by 24% using AI scheduling tools.

Key Highlights:

- Planning Time: Reduced by up to 90%.

- Production Capacity: Increased by 24%.

- On-Time Delivery: Improved by up to 3.5x.

- Waste Reduction: Scrap rates cut by 30%.

- Predictive Maintenance: Prevents downtime by anticipating failures.

AI systems continuously process live data from IoT sensors, inventory systems, and shop floor operations, enabling dynamic scheduling that adjusts instantly to disruptions. Tools like GoSmarter further optimise inventory, reduce scrap, and save hours of manual work. These advancements help manufacturers manage complexity, improve efficiency, and stay competitive in a fast-changing industry.

Common Production Scheduling Problems in Metals Manufacturing

Metals manufacturers face a web of scheduling challenges that manual processes simply can’t untangle. The complexity of operations - balancing equipment capacity, labour, material specifications, and fluctuating customer demand - leaves little room for error. Even small missteps can erode already tight profit margins. These issues, from last-minute order disruptions to unexpected equipment failures, call for a more adaptable and responsive approach to scheduling.

Rush Orders and Demand Changes

When a rush order comes in, it throws a wrench into static schedules, forcing planners to scramble. In metals manufacturing, where high-mix, low-volume operations are the norm, shared equipment must handle multiple jobs with intricate routings. Spreadsheets and manual tools just can’t keep up when priorities shift, leaving manufacturers stuck reacting instead of planning strategically.

This challenge is worsened by what experts term “signal decay” - outdated forecasts that lead to misaligned operations. As RELEX Solutions explains:

“What supply chain shocks do is expose the brittleness of static planning - they are unable to recalibrate when constraints shift in a short space of time” [3].

The numbers back this up: half of supply chain companies now list disruptions and shortages as their biggest operational hurdle.

Equipment Bottlenecks and Downtime

Bottlenecks in metals manufacturing are notoriously hard to predict, with constraints shifting between processes throughout the day. Manual scheduling tools can’t keep up with these changes, leading to wasted capacity and inflated costs. The problem becomes even more pronounced in flexible manufacturing setups, where frequent retooling and changeovers are required. Without careful planning, these pauses eat away at production throughput.

Unplanned downtime only makes things worse. Without real-time visibility into machine performance, planners are left guessing, unable to anticipate breakdowns or adjust schedules effectively. A single equipment failure can quickly snowball into a facility-wide delay, creating a domino effect that disrupts the entire production flow.

Inventory Imbalances and Material Delays

On top of scheduling and equipment challenges, managing materials in metals manufacturing requires precision that manual systems just can’t provide. Inventory must be tracked by detailed attributes like heat numbers, gauge, grade, and mechanical test results [1]. Spreadsheets struggle to handle these specifics, often leading to compliance issues and production stoppages.

Another common issue is the handling of remnants / offcuts / scrap - leftover material from cuts. Without proper tracking, these usable materials often go unnoticed, prompting unnecessary purchases of raw stock. This creates a cycle of inefficiency where manufacturers either tie up capital in excess inventory or face shortages that bring production to a standstill.

How AI Improves Production Scheduling in ERP Systems

AI is reshaping the way production scheduling is managed by replacing outdated, static processes with agile, real-time solutions. Traditional ERP scheduling often relies on batch updates - sometimes only weekly or monthly - leaving manufacturers exposed to disruptions like rush orders, equipment breakdowns, or inventory shortages. These static systems simply can’t keep up with the unpredictable nature of modern manufacturing. AI-driven systems, however, continuously process live data from IoT sensors, machine health monitors, and inventory systems. This allows for constant recalibration of schedules, enabling manufacturers to switch seamlessly between push planning (based on available materials) and pull planning (driven by immediate demand) as conditions evolve throughout the day [3]. This dynamic approach is a game-changer for production scheduling.

Real-Time Data Integration and Schedule Optimisation

AI effectively bridges the gap between high-level ERP strategies and the practical realities of the shop floor. By pulling data from sources like Manufacturing Execution Systems (MES), IoT devices, and ERP platforms such as SAP S/4HANA, AI identifies and highlights critical signals - whether they’re point-of-sale trends or machine alerts - while filtering out unnecessary noise [3][8]. This ensures that planners can focus on what truly matters without being overwhelmed by irrelevant data.

With dynamic scheduling tools, planners gain the ability to make instant adjustments, such as drag-and-drop job reassignments. AI immediately recalculates delivery timelines and machine capacity across the facility [6]. The impact of these tools in real-world scenarios has been remarkable: production planning time has been slashed from two hours to just two minutes, production line capacity has increased by 24%, and on-time deliveries have improved by 3.5 times [2]. These advancements directly address the inefficiencies and delays that plague traditional manual scheduling.

Predictive Analytics for Disruption Management

Predictive analytics take scheduling a step further by using IoT sensor data to foresee equipment failures, allowing maintenance teams to act before issues escalate. AI doesn’t just forecast potential delays; it analyses progress and machine availability to predict whether delivery targets can still be met. If risks are identified, it can recommend specific actions, such as reallocating resources or tweaking equipment usage, to keep production on track [8][9]. This proactive approach tackles downtime and equipment bottlenecks head-on - challenges that manual systems struggle to anticipate.

Take MAAG Food, Estonia’s top meat producer, as an example. In 2023, under the guidance of Director of Business Development Martin Küüsmaa, the company implemented AI-driven forecasting for over 300 SKUs. The results were impressive: 96% of demand forecasts required no manual intervention, and overall planning efficiency improved by 22% [3]. Similarly, Blount Fine Foods adopted AI for waste-aware production planning across 1,500 SKUs. Directed by Sr. Director of Demand Management Jonathan Wells, this initiative reduced finished goods waste by 35% and improved production efficiency by 2%, thanks to optimised scheduling that minimised changeovers [3].

Constraint-Based Planning for Complex Workflows

AI also excels at managing the intricate constraints of modern manufacturing. By evaluating variables like machine capacity, material availability, labour schedules, energy costs, and specific process requirements, AI generates schedules that maximise key objectives such as cost efficiency, margin, or order fulfilment rates [4]. Unlike traditional rule-based methods, AI uses advanced optimisation algorithms to craft the best possible schedules in real time. It can also simulate “what-if” scenarios, allowing manufacturers to explore the potential impact of disruptions or changes before they occur [3][4]. This capability is particularly valuable for industries dealing with inventory imbalances or material delays.

One standout example is Atria, a leading meat supplier in Finland. In 2024, under the leadership of SVP Tapani Potka, Atria harnessed machine learning to process retail data, achieving 98.1% weekly forecast accuracy and reducing manual forecast adjustments by 13% [3]. Studies further reveal that AI-powered scheduling can cut the time needed to create complex schedules by up to 90% and reduce overall scheduling costs by 5–15% [4].

Key Features of AI-Powered ERP Scheduling

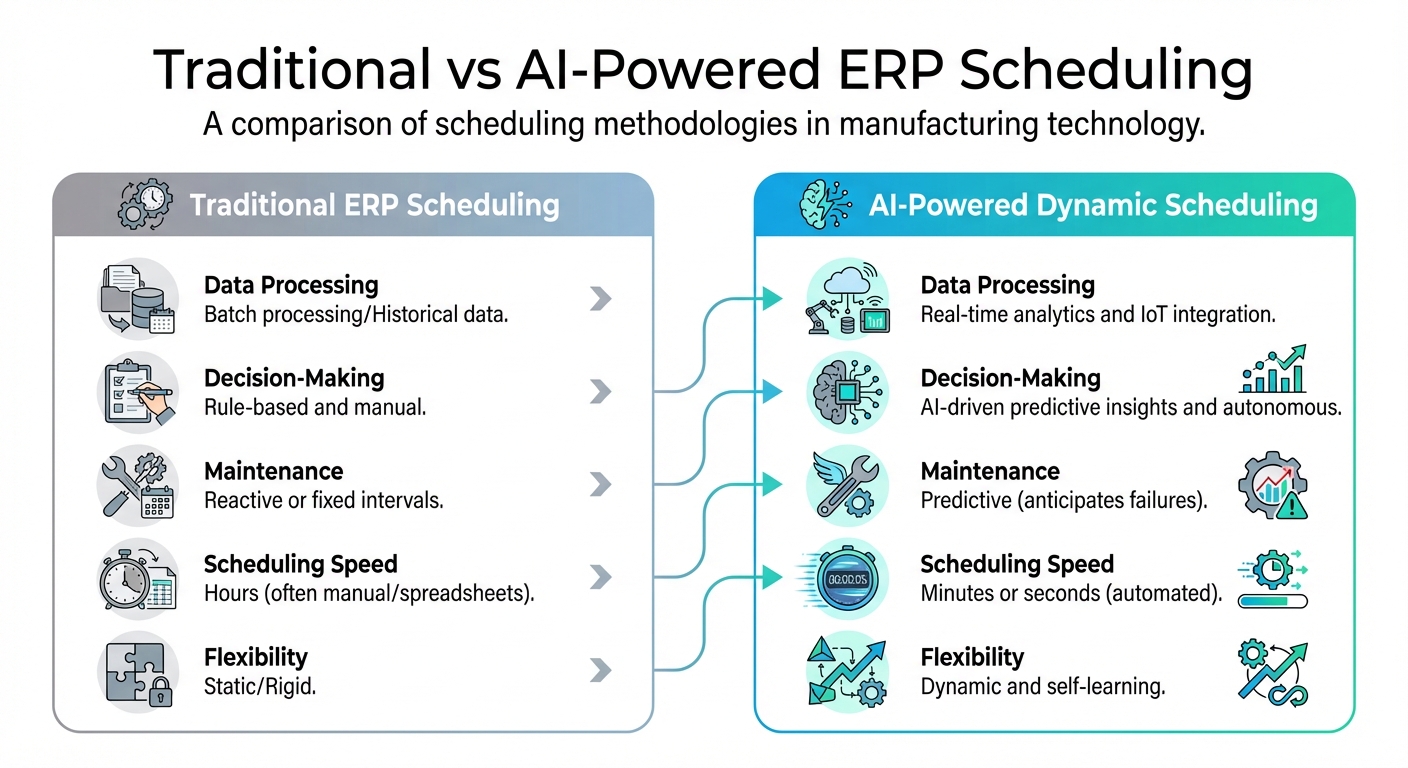

Traditional vs AI-Powered ERP Scheduling Comparison

alt:Traditional vs AI-Powered ERP Scheduling Comparison

AI-powered ERP systems are reshaping production scheduling by offering tools that adapt to real-world challenges. Unlike traditional systems that rely on static planning, these advanced tools continuously process live data from machines, materials, and workforce availability, creating schedules that adjust in real time.

Dynamic Scheduling and Order Prioritisation

With dynamic scheduling, planners can tackle disruptions head-on. Instead of manually recalculating spreadsheets for hours, AI systems can reoptimise schedules in seconds. Drag-and-drop interfaces make it easy to reallocate jobs, instantly updating delivery timelines and resource needs. Plus, planners can run “what-if” simulations to weigh up factors like speed, cost, and resource usage before locking in changes [6][11].

An important distinction these systems handle is between Available to Promise (ATP) and Capable to Promise (CTP). ATP determines what can be delivered based on current inventory, while CTP factors in raw materials, labour, and machine availability. AI ensures both are calculated in real time, so customer commitments remain achievable [10].

Examples of recent implementations show dramatic improvements, including faster scheduling and increased production capacity. By integrating dynamic scheduling with predictive maintenance, these systems boost reliability and efficiency.

Predictive Maintenance and Downtime Prevention

AI-powered predictive maintenance keeps production lines running smoothly by identifying potential equipment failures before they happen. Using real-time data from IoT sensors - monitoring metrics like temperature, vibration, and wear - AI flags machines at risk of breaking down and recommends timely maintenance actions [8]. This proactive approach minimises disruptions, as it not only predicts failures but also schedules maintenance at optimal times.

Integration with shop floor systems enhances this further. If a potential downtime issue is detected, the AI automatically adjusts schedules, rerouting jobs to other machines to maintain delivery timelines [8].

Capacity Planning and Bottleneck Analysis

AI doesn’t just react to disruptions - it continuously monitors overall production capacity to prevent bottlenecks in the first place. By providing real-time insights into machine workloads and available capacity, these tools help manufacturers avoid overloading work centres [6].

Some systems, like C3 AI Production Schedule Optimisation, go a step further by offering detailed “evidence packages” that highlight the root causes of bottlenecks. This transparency empowers schedulers to understand cost drivers and constraints [11]. By analysing thousands of variables - materials, labour, capacity - AI ensures production flows smoothly, even when demand shifts unexpectedly.

| Feature | Traditional ERP Scheduling | AI-Powered Dynamic Scheduling |

|---|---|---|

| Data Processing | Batch processing/Historical data | Real-time analytics and IoT integration |

| Decision-Making | Rule-based and manual | AI-driven predictive insights and autonomous |

| Maintenance | Reactive or fixed intervals | Predictive (anticipates failures) |

| Scheduling Speed | Hours (often manual/spreadsheets) | Minutes or seconds (automated) |

| Flexibility | Static/Rigid | Dynamic and self-learning |

GoSmarter’s Role in AI ERP Scheduling for Metals Manufacturing

GoSmarter

Traditional ERP systems often excel at high-level planning but struggle to capture the real-time details of shop floor operations. GoSmarter steps in to fill this gap with its AI-powered platform tailored specifically for metals manufacturers. From automating mill certificate processing to streamlining production planning and compliance tracking, GoSmarter offers a practical solution to the unique challenges faced by the industry.

AI-Driven Production Planning and Inventory Management

GoSmarter’s AI-driven production planning transforms how metals manufacturers manage inventory and scheduling. A standout feature is the Long Product Production Planner, which creates optimised cutting plans by analysing open orders and available stock. This tool has been proven to reduce scrap rates by 50% - a result demonstrated during testing with Midland Steel, where the impact on profitability was immediate [12].

The platform also eliminates the reliance on manual spreadsheets by introducing automated inventory management. Updating supplier data, stock levels, and orders is easy and aligns into a number of processes. Manufacturers can easily upload their existing inventory and order spreadsheets, allowing them to generate production plans right away. This seamless integration ensures that teams can adopt AI scheduling without the need for a complete workflow overhaul [12].

Real-Time Insights and Workflow Automation

One of GoSmarter’s most valuable features is its AI-powered mill certificate digitisation. This tool automatically processes bulk material certificates - whether scanned documents or PDFs - and organises the data by heat code [12]. For one production manager, this automation saved over 120 hours per year in manual data entry [12].

The platform also enhances operational visibility with product lineage and traceability. By linking material data directly to inventory records, manufacturers can track which stock is used for specific jobs, such as welding. This ensures compliance and improves scheduling accuracy, a game-changer for metals manufacturers managing hundreds of heat codes and material specifications daily.

Compliance and Operational Efficiency

GoSmarter goes further by simplifying compliance tasks. It includes tools like an emissions calculator for carbon reporting and a scrap calculator to measure production waste [12]. These features align with the growing push towards sustainable manufacturing and ESG reporting, all without adding extra administrative burdens.

“Smart technology choices can have a direct, measurable impact on reducing carbon emissions in steel manufacturing. The integration of AI and digital tracking has significantly improved our operational efficiency and sustainability performance.” - Tony Woods, CEO, Midland Steel [13]

With a transparent, pay-as-you-go model, GoSmarter makes AI-powered scheduling accessible even to smaller metals manufacturers. Its tools address production challenges, reduce waste, and enable real-time adjustments, making it an essential resource for the industry.

Steps to Implement AI in ERP Scheduling

Implementing AI in ERP scheduling doesn’t mean you have to overhaul your entire ERP system. Instead, focus on three key areas: preparing your data, integrating AI with existing systems, and tracking performance to ensure continuous improvement.

Assess ERP Data Readiness

For AI to deliver accurate scheduling, your data must be reliable and complete. Start by reviewing your current planning processes to uncover gaps where data - like demand forecasts or machine statuses - is being collected but not effectively turned into actionable decisions. For instance, Tegel Foods found that while they had plenty of data, its quality was questionable, and they lacked the tools to properly analyse it [3].

Pay special attention to master data. Ensure that key elements such as Bills of Materials (BOMs), routings, and work centre definitions are accurate and up to date [5]. Missing details like lead times or sequence durations can lead to poor AI-driven decisions [14]. Consolidating all data into a single, unified source helps prevent “signal decay”, where outdated or inaccurate information disrupts production workflows [3][4].

It’s worth noting that 55% of supply chain leaders have increased their technology investments to address these challenges, with 42% allocating over £7.5 million [3]. With solid data foundations in place, you’re ready to move on to system integration.

Integrate AI Modules with Shop Floor Systems

Once your data is ready, the next step is to connect AI tools to your existing production systems. This can be achieved through API connections to your ERP, direct links to Manufacturing Execution Systems (MES) and IoT devices, or cloud-to-cloud integrations with inventory systems [14]. The objective here is to bridge the gap between high-level ERP plans and the realities of daily shop floor operations [6].

Before diving into integration, standardise part names and codes across all systems and confirm that machine and work centre capacity limits are accurately recorded in your ERP. This prevents the AI from overcommitting resources [14]. A phased rollout approach works best - begin with pilot projects to quickly demonstrate value, then gradually expand AI capabilities across your operations [3]. This step ensures alignment between strategic planning and real-time production activities, paving the way for ongoing performance monitoring.

Monitor Performance and Iterate

AI implementation doesn’t stop once systems are connected; it’s an evolving process. Regularly measure and refine AI performance to ensure continuous improvements. Set clear KPIs - such as waste reduction, throughput, or on-time delivery rates - before implementation to track ROI and build trust within your organisation [3].

Real-time visibility tools, like live dashboards and digital interfaces, can provide instant updates on job progress, machine status, and schedule adherence [6][5]. Early adopters have already reported significant reductions in waste and gains in efficiency [3].

To maximise results, run “what-if” scenarios to evaluate how changes in manufacturing parameters impact costs and throughput [4]. By allowing AI to handle repetitive, high-volume scheduling tasks, human planners can focus on strategic decisions and exceptions that require judgement [3]. Ultimately, success depends on organisational buy-in - stakeholders must trust the AI recommendations enough to follow them rather than overriding them [3].

Benefits and ROI of AI-Powered Scheduling for Metals Manufacturers

Building on the earlier discussion about implementation strategies, AI-powered scheduling brings transformative improvements in operational efficiency, delivery reliability, and resource management. These advancements directly address the scheduling challenges faced by manufacturers, turning traditional ERP limitations into a competitive edge.

Efficiency Gains and Cost Reductions

AI can slash production scheduling time by as much as 90% and reduce overall scheduling costs by 5–15%, potentially saving large-scale manufacturers up to £13.5 million annually [11][15]. Real-world examples show a 29% reduction in downtime and changeover conflicts [15], while resource utilisation increases by up to 25% - all without the need for additional capital investment or staff [3].

“To make our vision for APS a reality, we looked for a way to rapidly process large volumes of data in an intelligent, automated way… The AI solution is delivering excellent results against several key performance indicators.” - Bai Zhizhi, Order Management Senior Manager, Lenovo [2]

With advanced AI systems automating over 75% of the scheduling process [2], human planners can focus on strategic decision-making while routine tasks are handled seamlessly. These efficiency improvements directly address bottlenecks and the limitations of manual planning, enhancing operational flexibility and resilience.

Improved On-Time Delivery Rates

AI-powered scheduling improves On-Time In-Full (OTIF) performance by 10% [11], with general on-time delivery rates increasing by up to 20% [3]. Unlike static systems, dynamic AI scheduling adapts instantly to challenges like machine breakdowns, rush orders, or material delays.

In 2023, MAAG Food replaced manual spreadsheets with RELEX AI-driven touchless forecasting. According to Martin Küüsmaa, Director of Business Development, this change led to 96% of demand forecasts requiring no manual intervention and a 22% boost in planning efficiency [3]. By automating routine tasks, planners can dedicate their time to handling exceptions, effectively managing the volatility of demand.

Resource Optimisation and Waste Reduction

AI-driven scheduling enhances material usage through intelligent planning, cutting production waste by up to 30% across the manufacturing sector [3]. For metals manufacturers, this translates into reduced scrap and better material efficiency, addressing inventory imbalances and remnant tracking issues.

Companies that adopt AI solutions report a 13% ROI, more than double the industry average of 5.9% [16]. These improvements in resource optimisation not only streamline operations but also strengthen production planning, ensuring metals manufacturers remain competitive while building resilience across their workflows.

Conclusion

AI-powered ERP systems are reshaping production scheduling, turning it from a manual, static process into a dynamic, self-adjusting operation. These systems can juggle countless variables - like equipment capacity, material availability, energy supply, and workforce constraints - all while continuously fine-tuning schedules for maximum efficiency [2].

The benefits for manufacturers are striking. Planning times that once took hours can now be completed in minutes. On-time deliveries can improve by up to 3.5 times, and production capacity can grow by as much as 24%, all without needing additional capital investment [2].

AI also addresses some of the industry’s toughest challenges. For instance, energy-integrated scheduling matches production needs with energy availability, cutting costs while contributing to decarbonisation goals [7]. Predictive maintenance reduces unexpected downtime, and constraint-based planning ensures resources are used efficiently, even when disruptions like rush orders or material shortages occur.

The numbers speak for themselves: 85% of packaging and print executives see AI as crucial for staying competitive [18], and 93% of manufacturers consider it a key driver of growth [17]. The conversation has shifted from debating whether to adopt AI-powered scheduling to focusing on how quickly it can be implemented, setting new standards for agility and operational performance.

For metals manufacturers looking to leave behind reactive approaches, AI-powered ERP scheduling offers a forward-thinking, data-driven solution for continuous improvement and operational success.

FAQs

How does AI enhance production scheduling in ERP systems for metals manufacturing?

AI is reshaping production scheduling within ERP systems by converting static data into actionable insights. By analysing real-time shop-floor information - like machine availability, labour schedules, inventory levels, and demand forecasts - AI can pinpoint constraints and create optimised job sequences. This enables manufacturers to foresee bottlenecks, manage disruptions effectively, and handle urgent orders with ease, all while cutting down on manual effort.

In the metals industry, AI-driven tools such as GoSmarter simplify operations by automating tasks like mill-certificate handling and inventory management. These systems integrate seamlessly with ERP platforms to develop efficient schedules, reducing time spent on paperwork and streamlining workflows. The outcome? Improved resource allocation, shorter lead times, and better on-time delivery rates.

How does AI help solve production scheduling challenges in metals manufacturing?

AI-powered ERP systems are reshaping metals manufacturing by turning rigid, reactive schedules into flexible, data-driven plans. They handle unexpected disruptions - like supply chain delays or sudden shifts in customer demand - by providing real-time visibility and tools to adjust production capacity and delivery timelines on the fly. This approach helps manufacturers make better use of resources, improve delivery performance, and increase overall efficiency.

These systems also play a role in sustainability by aligning production schedules with energy availability. This not only helps lower energy costs but also contributes to reducing CO₂ emissions. On top of that, they simplify labour-intensive tasks such as handling mill certificates and managing inventory, freeing up teams to focus on more strategic work. By addressing these challenges, AI allows metals manufacturers to operate with greater predictability, efficiency, and environmental responsibility.

How does AI-powered predictive maintenance help prevent unexpected downtime?

AI-powered predictive maintenance relies on real-time sensor data and machine learning models to keep a close watch on equipment performance. It spots early warning signs of potential problems, allowing issues to be addressed before they escalate into costly failures.

By tackling problems ahead of time, this method helps minimise unexpected downtime and avoids disruptions that can throw operations off track. Beyond that, it boosts efficiency, prolongs the lifespan of machinery, and helps manufacturers save both time and money - all while keeping production processes running smoothly.