10 Signs Your Metal Shop Needs Process Automation

- Steph Locke

- Blog

- December 12, 2025

Table of Contents

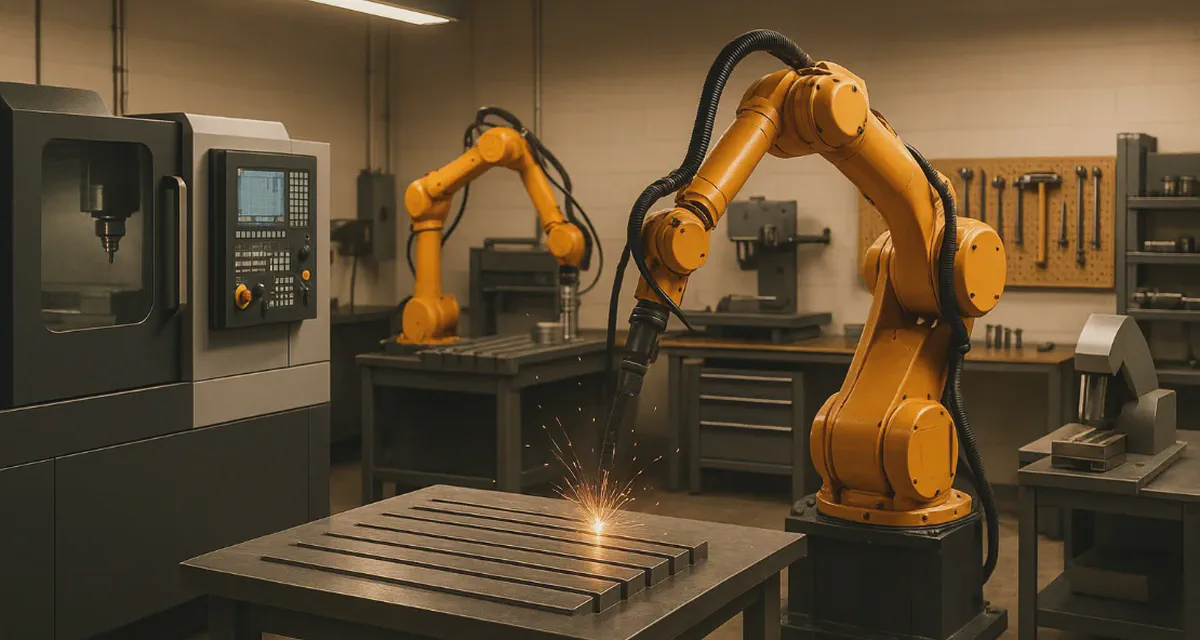

If your metal shop is struggling with rising costs, inconsistent quality, or meeting deadlines, it might be time to consider process automation. Automation can eliminate repetitive tasks, improve precision, and reduce waste, helping your shop stay competitive in a demanding market. Here are 10 clear signs that indicate your operations could benefit from automation:

- Repetitive tasks are time-consuming: Manual tasks like material handling and sorting slow down production and create bottlenecks.

- Product quality is inconsistent: Human errors during production lead to defects, wasted materials, and rework.

- Workflow bottlenecks are common: Delays at one stage disrupt the entire production process, causing inefficiencies.

- Labour costs are rising: Skilled workers are hard to find, and wages are increasing, making it harder to stay profitable.

- Meeting deadlines is a challenge: Manual processes limit scalability and make it difficult to handle surges in demand.

- Machine setup takes too long: Frequent manual setups lead to downtime and reduce overall productivity.

- Inventory management is error-prone: Manual tracking causes stock discrepancies, delays, and wasted materials.

- Compliance processes are slow: Manual documentation for industry standards and audits consumes time and resources.

- Limited access to production data: Without real-time metrics, decision-making and resource allocation suffer.

- Competitors are automating: Shops using automation deliver faster, more reliable results, leaving manual operations behind.

Automation doesn’t have to be overwhelming. Start small by targeting your biggest pain points, like reducing setup times or improving inventory accuracy. Over time, you can expand automation to other areas, boosting efficiency and cutting costs. If your competitors are already automating, now is the moment to act to avoid falling further behind.

1. Repetitive Tasks Take Up Too Much Time

When your team spends a large chunk of their day on routine manual tasks - like loading materials, positioning workpieces, feeding sheet metal into cutting machines, deburring parts, sorting components, or moving materials between workstations - it leaves less time for more skilled or creative work. These inefficiencies not only slow down production but also create bottlenecks during busy periods, increase the likelihood of mistakes, and make it harder to scale operations effectively.

Impact on Efficiency

Manual, repetitive work often creates bottlenecks that slow down production as a whole. Every hand-performed task takes time, and during peak demand, these delays can become a major issue. When machinists are tied up with basic tasks, they lose the opportunity to focus on improving processes or tackling more complex challenges. On the other hand, automated systems can run continuously without needing breaks, helping to streamline operations and increase production capacity when it’s most needed.

Reducing Errors and Waste

Repetition in manual tasks can lead to small but consistent errors - like slight misalignments or missed details - that add up over time. These mistakes often result in wasted materials and inefficient use of machines. By contrast, automation systems deliver consistent precision, significantly cutting down on errors. This not only reduces material waste but also minimises the need for rework, saving both time and resources.

Improving Scalability and Flexibility

Automation also makes it easier to scale your operations. When production depends heavily on manual labour, scaling up means hiring, training, and managing more staff - a process that’s both time-consuming and expensive. Automation allows you to increase output without a direct increase in labour costs. Many modern automation systems can also be reprogrammed to handle different tasks or product types, giving you the flexibility to adapt quickly to changing market demands. Relying solely on manual processes can limit your ability to stay competitive.

Cost Benefits of Automation

While automation requires an upfront investment, the long-term gains often outweigh the costs. Increased productivity, reduced waste, and fewer errors help recover those initial expenses quickly. Additionally, modular and scalable automation options allow even smaller metal shops to start small, automating their most repetitive tasks first and expanding as needed. This gradual approach makes automation more accessible and cost-effective for businesses of all sizes.

2. Product Quality Varies and Error Rates Are High

When parts rolling off your production line show inconsistent dimensions or finishes, it’s a clear sign that manual processes are struggling to keep up. Human error is inevitable, especially when workers face long shifts or manage intricate measurements and adjustments. Even seasoned machinists have days when things don’t go as planned, and slight differences in technique between operators can result in noticeable variations in the final product. These quality issues don’t just impact customer satisfaction - they can ripple across your entire operation.

Impact on Operational Efficiency

Quality inconsistencies can severely disrupt operational efficiency. High error rates mean more inspections and rework, slowing down production and delaying delivery schedules. They also introduce unpredictability into your workflow. When you can’t reliably forecast how many parts will pass inspection the first time, it becomes harder to plan production timelines or commit to delivery dates. To compensate, you may need to build in time buffers and keep larger inventories to account for potential rejects, tying up valuable space and capital in the process.

Reducing Errors and Waste

Automated systems can deliver a level of precision that manual processes simply can’t match. CNC machines, for instance, follow programmed parameters to cut with exact consistency every time, eliminating the variations that come with manual adjustments. This directly reduces scrap and material waste, which is especially important when working with costly metals and alloys. Even a small reduction in waste can translate into considerable savings.

Additionally, fewer rejected parts mean less energy spent on producing unusable components and less wear on machinery from unnecessary production cycles. Automated quality control systems, like vision systems and sensors, inspect parts in real-time during production. By catching defects early, they allow you to address issues immediately rather than discovering them after producing dozens - or even hundreds - of faulty parts.

Improving Scalability and Flexibility

Scaling production often introduces new challenges, particularly when quality depends on the skill and attention of individual operators. Training new staff takes time, and even with training, slight differences in technique can lead to inconsistent results. This makes scaling up risky when trying to meet growing demand.

Automation eliminates this bottleneck. Once a process is programmed and calibrated, multiple machines or production lines can run simultaneously, all delivering identical results. Scaling up no longer means compromising quality or spending months training new operators to match the expertise of experienced staff. Whether you’re producing 10 parts or 10,000, automated systems maintain the same level of precision.

Modern automation also offers flexibility. Many systems can store multiple programmes and switch between them quickly. This ensures each product variant is manufactured to its exact specifications without relying on operators to remember settings or make manual adjustments, further reducing the risk of errors.

Financial Benefits of Automation

The cost of high error rates goes far beyond wasted materials. Every rejected part represents lost labour, wasted machine time, and energy expenses that yield no return. Rework adds to this cost, often consuming as much time and resources as the initial production. On top of that, customer returns and warranty claims bring additional costs, including shipping, replacements, and potential damage to your reputation.

Investing in automation can quickly pay off by reducing these expenses. Lower scrap rates alone can recover a significant portion of the investment, while reduced rework frees up capacity for additional production. Automation also enables you to meet tighter tolerances and more reliable delivery schedules, which can attract clients with stricter quality demands - potentially allowing you to charge premium prices.

Even automating a single high-error process can yield immediate returns through reduced waste, fewer reworks, and greater customer confidence. These benefits highlight why streamlining operations with automation is a smart move for any metal shop aiming to stay competitive.

3. Production Workflow Has Regular Bottlenecks

When certain stages in your production process consistently slow everything down, you’re dealing with bottlenecks that can throw your operations off track. For instance, your cutting department might breeze through its tasks, only for parts to pile up while waiting for welding or finishing. These delays lead to idle machines, workers stuck waiting for materials, and missed production deadlines. A bottleneck in welding, for example, can hold up every subsequent step, creating a domino effect that disrupts the entire workflow. This imbalance doesn’t just slow things down - it highlights inefficiencies that ripple through every stage of production.

Impact on Operational Efficiency

Bottlenecks can grind your production to a halt. When work piles up at one stage, processes upstream stop because there’s no room for completed items, while downstream operations sit idle, waiting for materials to arrive. This creates a vicious cycle where expensive equipment and skilled workers are underutilised.

The problem doesn’t stop there. Queued-up work takes up valuable floor space and ties up working capital, increasing the risk of damage or errors during handling. Manual coordination often makes things worse, as supervisors spend their time juggling priorities instead of focusing on improving the overall process.

Ability to Improve Scalability and Flexibility

Bottlenecks become even more challenging when your business starts to grow. Expanding capacity in one area won’t solve the issue if another stage remains a choke point - you’re just moving the problem elsewhere. This is where automation can make a difference. Automated systems redistribute workloads dynamically, allowing slower stages to catch up without constant manual adjustments. For example, robots can work through backlogs overnight, and automated material handling systems can ensure parts move smoothly between stations without human intervention.

Automation also brings much-needed flexibility. Programmable systems can adjust to changing priorities far more easily than manual processes, where staff often have fixed roles and limited adaptability.

Cost-Effectiveness of Automation Solutions

Investing in automation to tackle bottlenecks can pay off quickly. Removing a single constraint can unlock significant production capacity, turning potential revenue losses into gains. Even a modest investment in automation can recover lost output and improve overall efficiency.

Beyond boosting capacity, automation reduces storage costs and frees up working capital. With fewer work-in-progress items cluttering your facility, you’ll spend less on storage and handling. A smoother workflow also lightens the load on your team, which can help lower turnover rates and cut the costs of hiring and training new staff. Plus, more predictable lead times can enhance customer satisfaction, making your business more attractive to clients who value reliability.

The good news? You don’t have to automate everything all at once. Tackling bottlenecks one step at a time is a smart move towards streamlining your production process and boosting overall performance.

4. Labour Costs Are Rising and Staff Are Hard to Find

Finding skilled metal fabrication workers in the UK has become a real challenge. Welders, machinists, and CNC operators are in short supply, and those with the right expertise are commanding higher wages. For many metal shops, this creates a double-edged problem: not only is it harder to recruit talent, but rising wage demands also add to the pressure. The result? Overworked employees, rushed production, and delays that can disrupt customer commitments and slow down business growth. These staffing issues directly affect how efficiently operations run.

Impact on Operational Efficiency

Labour shortages pile onto existing challenges like repetitive tasks and quality concerns. When staff numbers are stretched thin, longer working hours become the norm, which can lead to fatigue, more mistakes, and even workplace accidents. If key team members are unavailable - whether due to illness or turnover - the workload often falls to less experienced employees, creating further inefficiencies.

On top of this, recruitment and training take time. Specialised equipment requires skilled operators, and getting new hires up to speed can be a lengthy process. During this period, experienced staff often have to step away from their main duties to train new employees, which can slow production even more.

Ability to Improve Scalability and Flexibility

Automation presents a practical way to address these challenges. By handling increased production volumes without needing more staff, automated systems free up skilled workers for more valuable tasks like quality control, programming, or improving processes.

Unlike human workers, automated systems don’t get tired, distracted, or need breaks. They can operate for extended hours or across multiple shifts, giving you the flexibility to meet customer demands more effectively. This also opens the door to taking on jobs that might not have been feasible with manual methods alone.

Cost-Effectiveness of Automation Solutions

The cost of maintaining a manual workforce goes far beyond wages - it includes National Insurance, pension contributions, holiday pay, sick leave, overtime, and the expenses tied to recruitment and training. These costs continue to rise, making a fully manual operation increasingly expensive. While automation requires an initial investment, it provides long-term savings and stabilises costs. Automated systems not only offer greater precision but also reduce risks linked to staff turnover and wage inflation, giving businesses a more predictable financial outlook.

When high labour costs make your quotes less competitive or when staffing shortages limit your ability to fulfil orders, you risk missing out on valuable opportunities. By adopting automation, you can tackle these challenges head-on, ensuring more reliable production and a stronger foundation for future growth.

5. Meeting Deadlines or Scaling Up Is Difficult

After dealing with repetitive tasks and quality issues, the challenge of meeting deadlines often becomes the next hurdle. Manual processes have their limits, and when demand surges - whether from loyal clients or new opportunities - these limitations become glaringly obvious. Missed deadlines don’t just tarnish your reputation; they can also lead to lost revenue and customers exploring other options.

Impact on Operational Efficiency

Manual tasks like material handling, machine setup, cutting, welding, and finishing require a set amount of time. This fixed pace caps how fast you can work. When orders start piling up, speeding up production without sacrificing quality becomes nearly impossible, leaving your team stretched thin.

The problem gets worse when managing multiple projects simultaneously. Each job change means resetting machines and tools, which eats into production time and causes delays. If one job runs late, it creates a domino effect, pushing back subsequent tasks and leaving customers waiting while your team scrambles to catch up.

Trying to scale up manually often means hiring more people, buying additional equipment, and expanding your workspace. These steps take significant time and financial resources. Even after hiring, it can take weeks or months to train new staff to work efficiently, leaving your shop struggling during busy periods.

How Automation Transforms Scalability and Flexibility

Automation changes the game entirely. Automated systems can operate continuously, increasing production capacity without needing extra staff. This extended runtime allows you to handle higher demand without a matching rise in labour costs.

Modern automated equipment also excels at handling changeovers. For example, CNC machines with automatic tool changers or robotic welding cells can switch tasks in just minutes. This adaptability means you can handle everything from small custom jobs to large-scale production runs without the bottlenecks that manual processes often create.

When new orders come in, automated systems give you the flexibility to adjust production quickly. Instead of being restricted by staff availability, you can scale operations up or down to meet demand. This agility lets you confidently bid for larger contracts and take on rush jobs that would otherwise be out of reach with manual methods alone.

The Cost Benefits of Automation

Missed deadlines don’t just hurt your reputation - they also come with financial penalties, reduced profit margins, and the risk of losing future business. Turning down work due to limited capacity adds another layer of hidden costs.

Automation offers a solution by providing reliable, scalable production capacity that isn’t tied to staffing constraints. While the upfront investment requires careful consideration, the benefits - such as consistently meeting deadlines, taking on bigger projects, and running extended shifts - often lead to a quick return. Many metal shops find that automation allows them to handle significantly more work without a corresponding increase in labour costs. This not only strengthens their competitive edge but also opens the door to new business opportunities.

If your manual processes are holding you back and causing delays, it’s clear that automation isn’t just an option - it’s a necessity.

6. Manual Machine Setup Causes Too Much Downtime

Manual machine setups are a major time sink in production. Adjusting fixtures, calibrating tools, and preparing machines for operation can eat up valuable hours, especially if you’re managing multiple jobs in a single day. This downtime quickly adds up, creating a significant bottleneck in your workflow.

Impact on Efficiency and Scheduling

When setup times vary, it becomes tricky to plan production schedules effectively. This unpredictability can make it hard to provide accurate delivery timelines, frustrating customers and straining operations. Plus, when skilled workers are tied up with repetitive setup tasks, their expertise is wasted on jobs that don’t require their full potential. It’s a hidden cost that drags down overall productivity.

Repeatedly handling heavy fixtures also takes a toll on operators, leading to fatigue and increasing the chances of mistakes as the day goes on. These errors can be costly, both in terms of materials and time.

Reducing Errors and Waste

Even a small setup mistake - like an incorrect offset or a misaligned fixture - can ruin an entire batch of parts. This not only wastes materials but also delays production and impacts customer satisfaction. Automation offers a way out of this cycle.

With tools like automated pallet changers, tool changers, and work holding systems, setups become consistent and error-free. Operators can then focus on higher-value tasks like quality control and process improvement rather than wrestling with manual setups. Fewer errors mean less waste, faster production, and a smoother workflow overall.

Boosting Scalability and Flexibility

Manual setups can cap the number of jobs you can handle in a day, especially if you’re dealing with frequent changeovers for small batch sizes or custom orders. Automation changes the game by slashing setup times, making it easier to take on smaller or more customised jobs without sacrificing efficiency.

Automated systems also open the door to more flexible production methods, like lights-out manufacturing, where machines run unattended during off-hours. This approach can significantly expand your production capacity without adding shifts or increasing labour costs.

Is Automation Worth It?

Investing in automated setup processes can feel like a big step, but the payoff is hard to ignore. By cutting downtime, these systems ensure machines spend more time producing and less time idle. While the upfront cost depends on the complexity of the system, many shops see a quick return on investment through increased efficiency and reduced waste.

Automation also helps address staffing challenges by lowering the reliance on highly experienced operators for routine setups. If your setup time is eating into productive machine hours, it might be time to explore automation as a way to enhance productivity and profitability.

7. Inventory Management Is Inefficient or Full of Errors

After tackling production bottlenecks and staffing hurdles, another major challenge many metal shops face is inventory management. Keeping track of raw materials, work-in-progress, and finished goods can feel like juggling too many balls at once. When you’re relying on spreadsheets, manual counts, or outdated systems, things can quickly go off the rails. Misplaced stock, incorrect counts, and missing paperwork create confusion that ripples through every part of your operation.

The trouble often starts with how information is recorded. Imagine someone scribbles a material transfer on a scrap of paper, forgets to update the system, or accidentally enters the wrong quantity. These small mistakes lead to big discrepancies between what’s recorded and what’s actually available. Suddenly, you’re left guessing what’s in stock, leading to rushed orders, delayed production, and unhappy customers. This inefficiency hits your shop floor hard.

Impact on Operational Efficiency

Unreliable inventory data throws a wrench into your operations. When stock levels are off, you might over-order materials, tying up cash and cluttering your warehouse. On the flip side, running out of essential materials mid-production can leave machines idle while you wait for emergency deliveries.

Every day, valuable time is wasted searching for materials. Operators lose minutes - or even hours - hunting for the right steel grade or tracking down mill certificates instead of focusing on their actual work. This constant interruption disrupts workflows and makes it nearly impossible to stick to consistent production schedules. If your team doesn’t know what’s available or where to find it, planning becomes guesswork.

This uncertainty also damages customer relationships. You might promise a delivery date based on stock you think you have, only to realise too late that the material is already allocated - or worse, doesn’t exist.

Reducing Errors and Waste

Manual tracking is a breeding ground for errors - whether it’s transposed numbers, typos, or misread entries. Over time, these mistakes build up, making your inventory data less and less reliable.

Traceability is another major pain point. If your records are incomplete or inaccurate, matching materials to mill certificates or tracing which batch went into a specific customer order becomes a nightmare. This is especially problematic in industries with strict quality standards, where full traceability isn’t just nice to have - it’s mandatory.

Automated inventory systems tackle these issues head-on by capturing data at the source. When materials arrive, move, or leave, the system updates in real-time. This ensures your records always reflect actual stock levels, cutting down discrepancies and boosting accuracy.

These Inventory management systems can also simplify traceability by linking mill certificates and documentation directly to specific materials. Whether you need records for production planning or a customer audit, you can access them instantly, saving time and reducing stress.

Supporting Growth and Flexibility

As your business grows, inventory errors can spiral out of control. What’s manageable with a small number of materials and clients becomes overwhelming when you’re dealing with hundreds of SKUs and multiple projects at once.

Automated systems make scaling up much easier. The software can handle large inventories just as efficiently as small ones, meaning you can expand without drowning in admin work. This capability is especially valuable if you’re planning to take on larger contracts or diversify your product offerings.

With better inventory visibility, production planning becomes more flexible. Knowing exactly what materials are available and where they are allows you to streamline job scheduling, reduce material handling, and cut down on changeover times. This flexibility lets you adapt quickly to rush orders or shifting priorities without creating chaos on the shop floor.

Financial Benefits of Automation

The cost of poor inventory management often flies under the radar. Excess stock ties up capital that could be used elsewhere. Emergency orders come with premium pricing and expedited shipping fees. And lost or misplaced materials are pure waste, eating directly into your profits.

Automation addresses these hidden costs while boosting overall efficiency. Modern inventory systems don’t require huge upfront investments or complicated setups. Cloud-based platforms, for instance, offer flexible pricing that scales with your needs, making them accessible even for smaller operations.

The return on investment comes quickly. Reduced material waste, fewer emergency orders, and better cash flow management all add up. Plus, when your team spends less time searching for materials, they can focus on work that actually drives value.

For metal shops handling compliance-heavy projects, automated systems offer another layer of support. They simplify traceability and documentation, making it easier to retrieve mill certificates and track material origins. This not only saves time during audits but also lowers the risk of costly compliance issues.

If your team is constantly scrambling to locate materials, your stock counts never match reality, or you’re frequently caught off guard by inventory shortages, automation could completely change how you manage materials and documentation in your shop. It’s a game-changer for efficiency, accuracy, and growth.

8. Manual Compliance Processes Slow Down Operations

After tackling inventory chaos, another hurdle looms large: compliance. For metal shops, meeting industry standards and customer expectations isn’t optional - it’s a core part of the job. Whether it’s aerospace specifications, construction regulations, or automotive quality benchmarks, the paperwork can feel endless. And when compliance processes rely on manual methods, they can eat up valuable production time.

The root of the issue lies in how compliance documentation is handled. Tasks like matching mill certificates to materials, filing test reports, and maintaining traceability records for years are often done manually. Storing this information in filing cabinets or spreadsheets creates a heavy administrative load, slowing down production and disrupting workflow.

Impact on Operational Efficiency

Manual compliance processes create significant bottlenecks. For example, if a customer requests material certificates for a completed order, someone has to pause their work, dig through files, and match the necessary documents. Depending on how organised your records are, this could take hours - or even days.

Audits make the situation worse. Preparing for a quality audit or customer inspection often involves pulling together mountains of paperwork, verifying traceability records, and ensuring every document is accurate. If your records are scattered across physical files or multiple systems, this preparation can pull staff away from their primary tasks.

Even day-to-day production suffers. Picture a machinist needing to verify material specifications before starting a job. If they have to locate the mill certificate manually, the machine sits idle, wasting time. Multiply this by several jobs and operators, and the productivity loss adds up quickly.

Customer service also takes a hit. When clients ask for documentation, they expect prompt responses. Searching through manual records can delay answers, leaving a poor impression and raising questions about your operational efficiency. In competitive industries, this could cost you future business.

Potential to Reduce Errors and Waste

Handling compliance documents manually increases the risk of errors. Common mistakes - like attaching the wrong certificates, misfiling documentation, or incorrectly recording batch numbers - can lead to compliance issues. These errors not only disrupt production but can also result in customer complaints and urgent remediation efforts. In regulated industries, missing or incorrect documentation could mean rejected shipments, failed audits, or even legal penalties.

Traceability is another challenge. For instance, tracing which specific steel coil was used in a customer’s order six months ago depends entirely on accurate and well-organised records. A single missing link in the chain can undermine traceability, which is critical in industries with strict regulatory requirements.

Automated compliance systems can eliminate many of these risks. When materials arrive with mill certificates, an automated system digitises and links them to the correct inventory records on the spot. As materials move through production, traceability is maintained automatically. When you need documentation, it’s instantly accessible and accurate - no manual searching required.

Ability to Improve Scalability and Flexibility

As your business grows, manual compliance processes become harder to manage. While a manual system might work for a dozen orders a month, it quickly falls apart when you’re handling hundreds. The administrative workload grows exponentially, but hiring more staff to manage paperwork isn’t a sustainable solution.

Automation offers a way out. Whether you’re processing ten mill certificates or a thousand, automated systems handle them with the same efficiency. This scalability is especially important if you plan to expand into new markets, take on larger contracts, or diversify your offerings. Without automation, growth can feel like drowning in paperwork.

Digitised compliance systems also improve flexibility. When documentation is searchable and stored digitally, customer requests can be handled instantly - no matter how old the order or how complex the traceability requirements. This responsiveness can set you apart, especially when dealing with clients who have tight deadlines and high standards.

For businesses with multiple sites, automation is a game changer. Keeping compliance processes consistent across locations is nearly impossible with manual systems. Automated solutions ensure uniform procedures and centralised access to documentation, reducing risks and improving quality control across your operations.

Cost-Effectiveness of Automation Solutions

Just as automation can streamline production, it can also simplify compliance and cut hidden costs. Manual compliance processes come with steep expenses, including staff time spent on admin tasks, fees for rush documentation requests, and costs associated with errors or compliance failures. There’s also the opportunity cost of time that could be spent on tasks that add value.

Modern compliance automation doesn’t require a huge upfront investment. Many cloud-based platforms offer flexible pricing models that scale with your needs, making them accessible even for smaller metal shops. For example, platforms like GoSmarter provide pay-as-you-go options, so you only pay for what you use. Some even offer free plans to help you get started without financial risk.

The benefits of automation quickly outweigh the costs. By reducing errors, compliance-related mistakes and rework are minimised. Faster response times to customer requests improve satisfaction, which can lead to repeat business. And with better audit preparation, compliance reviews become less stressful and less costly.

Automation also boosts staff morale. Let’s face it - no one enjoys spending hours filing paperwork or searching for lost documents. By automating these tedious tasks, your team can focus on more rewarding and productive work. This not only improves job satisfaction but also reduces staff turnover, saving you money on recruitment and training.

For metal shops navigating strict compliance requirements - whether in aerospace, medical devices, or other regulated industries - automation isn’t just a convenience. It’s a critical tool for managing risk. The potential costs of compliance failures, from penalties to lost contracts and reputational damage, far outweigh the investment in automation. If your team spends hours retrieving certificates, dreads audit preparations, or has faced compliance issues with customers, it’s time to explore automation. The technology is there to make these processes faster, more accurate, and much less of a headache - allowing your team to focus on delivering top-quality products.

9. You Have Limited Access to Production Data and Metrics

Once compliance is addressed, another major hurdle is the limited access to production data. Many metal shops operate with minimal visibility into their shop floor activities. Decisions about scheduling, capacity, and resource allocation are often based on gut feelings, rough estimates, or outdated notes scribbled on whiteboards. Without accurate and timely data, it’s like driving without a map - you’re moving, but without clear direction.

This issue arises from how production data is (or isn’t) collected. In many cases, information is scattered - handwritten job sheets, verbal updates from supervisors, machine logs that no one checks, and sporadically updated spreadsheets. There’s no single system to bring it all together. By the time you piece together the data, it’s already outdated. This lack of centralised, real-time data makes it incredibly difficult to make informed decisions, whether it’s about scheduling or allocating resources.

Impact on Operational Efficiency

When you don’t have access to accurate production metrics, inefficiencies pile up fast. Take job durations, for example. Without real-time updates, they’re often based on guesses or outdated data. This makes it nearly impossible to identify problems as they happen.

Machine utilisation is another blind spot. You might assume your CNC machines are running at full capacity, but without data, you can’t know for sure. One machine might be idle for hours while another is overloaded. Without metrics on run times, setup times, and downtime, these imbalances go unnoticed and unresolved.

Customer commitments also suffer. Delivery dates are often based on perceived capacity rather than actual data. This leads to missed deadlines or lost opportunities, both of which cost you money.

Even staff productivity becomes hard to measure. Which tasks are taking longer than expected? Where are the bottlenecks? Which team members might need extra training? Without data, these questions remain unanswered. You might sense that productivity could improve, but pinpointing the problem - or measuring the impact of any changes - is nearly impossible.

This lack of data affects every decision you make. Should you invest in a new machine? Hire more staff? Accept a large contract? Without solid data on your current performance and capacity, these decisions become risky guesses, often leading to overspending or missed opportunities.

Potential to Reduce Errors and Waste

Limited data visibility doesn’t just slow you down - it also makes it harder to control quality and reduce waste. Without real-time data, trends in quality issues can go unnoticed for days or even weeks, often until a customer complains or an inspector flags a problem.

Material waste is another area that suffers. How much scrap are you generating? Which jobs or processes are causing the most waste? Without proper tracking, these questions are impossible to answer. You might notice the scrap bin filling up faster than usual, but you won’t know why or how to address it.

Real-time data changes this. It allows you to identify trends in scrap and rework, making it easier to fix issues before they escalate. Instead of addressing symptoms, you can tackle root causes.

Automated systems make this process seamless. A centralised platform provides real-time insights into production performance, including machine activity, job progress, quality metrics, and material usage. If a job is running behind schedule, you’ll know immediately. If scrap rates spike, you can investigate before costs spiral. If a machine’s performance dips, you can schedule maintenance before a breakdown occurs.

This isn’t just about reacting faster; it’s about preventing problems altogether. Analysing trends over time can reveal patterns. For example, if certain jobs consistently take longer on Mondays, it might point to a training issue after the weekend. Or if scrap rates rise when using a specific supplier, it could indicate a problem with their materials. These insights are only possible with comprehensive, real-time data.

Ability to Improve Scalability and Flexibility

As your shop grows, the challenges of managing production without proper data become overwhelming. What works for a small operation with a few machines and a close-knit team simply doesn’t scale when you’re running multiple shifts, dozens of machines, and complex schedules. Manual oversight can’t keep up.

Automated data capture provides the foundation for growth. With production metrics automatically collected and analysed, you can manage larger, more complex operations without drowning in information overload. Adding machines, taking on more customers, or expanding into new product lines becomes manageable because you have systems in place to track and optimise performance.

Flexibility improves as well. When a rush order comes in, you need to know immediately if it can fit into your schedule without disrupting existing commitments. Real-time data on machine availability, job progress, and capacity lets you make that decision confidently in minutes, rather than spending hours manually checking schedules and asking around.

For shops with multiple locations, the benefits are even greater. Comparing performance across sites is nearly impossible without standardised metrics. Which facility is more efficient? Where are there best practices to share? Automated data collection ensures consistency, making it easy to compare and improve performance across all locations.

Customer service also gets a boost. When clients ask for updates, you can provide accurate, real-time information instead of vague estimates. This builds trust and sets you apart from competitors who still rely on manual tracking and guesswork.

Cost-Effectiveness of Automation Solutions

Modern automation platforms make it easier and more affordable than ever to access production data. Cloud-based solutions, for instance, often come with flexible pricing models, including free plans or pay-as-you-go options. This makes it possible for even smaller shops to start capturing and analysing production data without a huge upfront investment.

The return on investment is clear. Better scheduling reduces machine idle time, boosting output without needing additional equipment. Improved quality control cuts down on scrap and rework, saving on materials and labour. More accurate capacity planning allows you to take on new work confidently, increasing revenue without overcommitting.

Your team benefits, too. With a centralised system, staff spend less time tracking down information and more time on productive tasks. Instead of walking the shop floor for updates or digging through paperwork, they can access everything they need in one place.

Strategic planning becomes much easier as well. Historical data can reveal trends in demand, capacity, and performance, helping you make informed decisions. Should you invest in a new laser cutter? The data will show whether your current machines are maxed out and whether the investment is worthwhile. Thinking about hiring more staff? Production metrics can pinpoint whether labour is the bottleneck or if the issue lies elsewhere.

For shops struggling to answer basic questions about production - how long jobs take, which machines are underutilised, where quality issues originate, or whether there’s capacity for new work - automation offers a clear way forward. The technology exists to automatically capture and analyse this data, providing the insights you need to run your operation more efficiently and profitably. If you’re still relying on incomplete information or gut instinct, it’s time to embrace a smarter approach.

10. Competitors Are Using Automation and Moving Ahead

If your competitors are outpacing you - delivering orders faster, quoting with precision, and winning contracts you once held - it’s likely they’ve embraced automation. Sticking to manual methods while others modernise isn’t just a matter of falling behind on trends; it’s about risking your position in an increasingly competitive market. Every delay in upgrading your processes gives competitors more time to widen the gap.

Many top-performing shops are now using automation as a benchmark for success. The metal fabrication industry has reached a point where those automating key processes are operating at a level of efficiency manual methods simply can’t match. While you might still be managing schedules on whiteboards or spreadsheets, automated shops enjoy real-time updates and smooth job transitions. This growing efficiency gap makes it harder to compete without modernising.

Impact on Operational Efficiency

Automation delivers efficiency gains that build over time. Automated setups and scheduling reduce downtime, maximise machine usage, and streamline production. When extended to areas like material handling, quality control, inventory management, and data tracking, the entire workflow becomes far more seamless. Competitors leveraging these systems can generate accurate quotes quickly because they have instant insights into their capacity and lead times. In contrast, manual methods often lead to delays and uncertainty, which can cost you opportunities.

Reducing Errors and Waste

Speed isn’t the only advantage of automation - it also improves consistency. Automated quality control systems catch defects early and ensure specifications are met throughout production. This leads to fewer rejections and less rework, which are common pain points in manual setups. Over time, manual processes can result in higher scrap rates and increased costs, whereas automated competitors benefit from faster checks and fewer errors, giving them a clear edge when quoting jobs.

On top of that, advanced software can optimise material layouts far better than manual methods. By improving material yield, automation directly reduces waste, lowering the cost per job. This allows shops with automated systems to offer competitive pricing without compromising on quality.

Scalability and Flexibility

Automation doesn’t just improve efficiency - it also makes scaling operations easier. Automated systems allow shops to extend run times, integrate new machinery, and handle larger workloads without sacrificing quality. This scalability is a game-changer when bidding for big contracts, as it ensures consistent results even with fluctuating volumes. Competitors with automation can confidently take on opportunities that might overwhelm manual operations.

The Cost Argument for Automation

Automation has become more accessible than ever. Modern cloud-based systems come with flexible pricing models that scale with your usage, making them more affordable to implement. The financial benefits are clear: automation reduces the need for hard-to-find skilled labour, cuts overtime costs, and mitigates risks tied to labour shortages. These savings allow automated shops to offer sharper quotes while maintaining healthy profit margins.

Delaying automation means risking your market share. Competitors who’ve already adopted these systems are building stronger customer bases, fine-tuning their processes, and reinvesting their savings into further improvements. With customers now expecting fast quotes, real-time updates, and reliable quality, sticking to manual methods could leave you struggling to keep up.

The takeaway is simple: automation in metal fabrication isn’t just a competitive edge anymore - it’s a necessity. The question isn’t whether you should automate, but how quickly you can make it happen. The technology is ready, the costs are manageable, and the benefits are undeniable. The sooner you start, the better positioned you’ll be to close the gap and stay in the game.

Conclusion

If your metal shop is showing any of these signs - lost time due to repetitive tasks, inconsistent quality, production slowdowns, or increasing pressure from modernised competitors - it’s clear that automation has become a necessity, not a luxury. The challenges you’re facing are likely interconnected, highlighting workflows that have outpaced manual methods and are now holding you back.

Inefficiencies tend to snowball across operations. Manual processes, while once sufficient, can no longer keep up with today’s demands. Automation addresses these issues head-on by eliminating repetitive tasks, stabilising quality control, and smoothing out production bottlenecks. It also provides real-time data for smarter decision-making and allows your skilled workers to focus on tasks that genuinely require their expertise, rather than wasting energy on administrative burdens like data entry or tracking down paperwork.

The good news? Automation is more accessible than ever. You can start small by targeting specific pain points - like managing mill certificates, tracking inventory, or improving production schedules - and scale up as you see the results. This incremental approach not only minimises disruption but also makes it easier to justify the investment.

Now’s the time to take a hard look at your shop. Are administrative tasks eating up valuable time? Are quality issues or bottlenecks costing you orders? Are rising labour costs squeezing your margins? If the answer to any of these is yes, it’s worth exploring how automation could transform your operations.

Platforms such as GoSmarter are specifically designed for metals manufacturers, offering AI-powered tools to streamline everything from compliance and certificate management to inventory and production planning. With a free plan to get started and a pay-as-you-go model that grows with your needs, it’s never been easier to take the first step. Plus, these platforms integrate with your existing systems, enhancing what already works rather than requiring a complete overhaul.

The metal fabrication industry is evolving quickly, and shops that hesitate risk falling behind. Your competitors are already investing in automation, improving their processes, and winning contracts with faster, more reliable, and cost-effective services. Delaying action only widens the gap, making it harder to catch up.

Automation isn’t just about keeping up - it’s about giving your team the tools to excel. It enables your shop to focus on high-value tasks, improve precision, and adapt to a market where speed and flexibility are no longer optional. Evaluate your shop today, pinpoint your biggest challenges, and take that first step towards automation. Start small, build on your successes, and position your business to thrive in a competitive landscape.

FAQs

What’s the best way to introduce automation into my metal shop without disrupting current operations?

To bring automation into your operations smoothly, it’s best to start small and focus on changes that are easy to manage. Pick one repetitive task - something simple to track and assess - and automate it first. Look for areas where delays or errors tend to happen, as these are often the best places to begin.

Take it step by step, expanding automation gradually as you see results and build confidence. You might also want to explore support from local programmes that offer advice or funding for manufacturing innovation. This can provide the guidance and resources needed to make the process easier and more efficient.

What cost savings and ROI can metal shops achieve with process automation?

Adopting process automation in metal fabrication can lead to noticeable cost savings. By cutting down on labour costs, reducing material waste, and making production processes more efficient, businesses can significantly lower their overall expenses. Automation also enhances efficiency, helping to eliminate delays and errors that might otherwise inflate operational costs.

When it comes to return on investment (ROI), many businesses experience payback within 12 to 36 months. This quick turnaround comes from higher productivity, consistent product quality, and less downtime - key factors that automation brings to the table. Over time, these improvements provide metal fabrication shops with a solid financial advantage, helping them stay competitive in a demanding market.

How does process automation improve product quality and consistency in a metal shop?

Automation plays a key role in improving product quality by cutting down on human error and ensuring consistent results throughout the production process. Automated systems excel at handling repetitive tasks with accuracy, eliminating the inconsistencies often associated with manual labour.

By streamlining processes, automation ensures products meet uniform specifications, which is essential for satisfying customer expectations and adhering to industry requirements. On top of that, it reduces waste and the need for rework, saving valuable time and resources while consistently delivering dependable, high-quality outcomes.